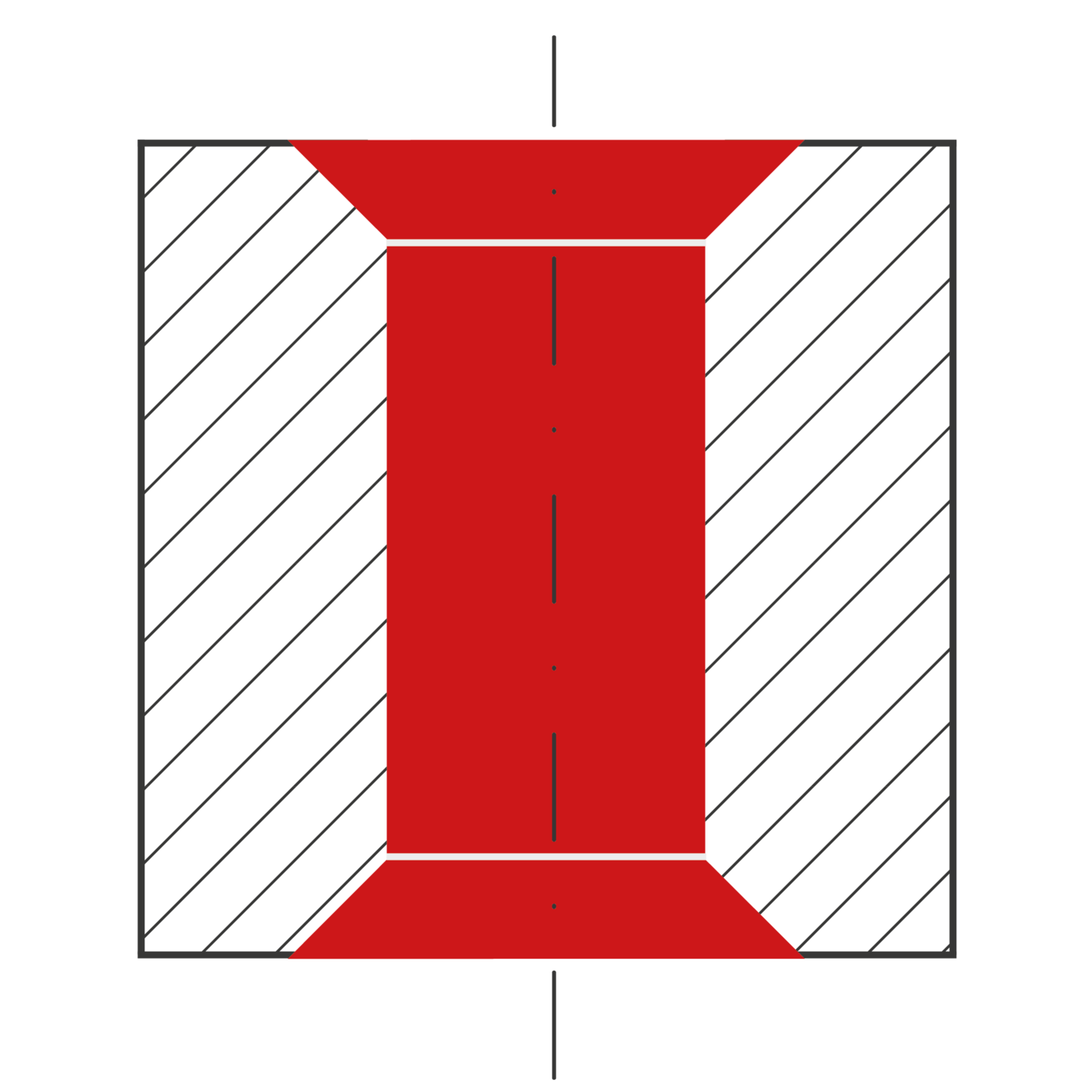

Brake disc

Multiple work steps in a single tool for maximum cost efficiency.

The automotive industry requires a vast quantity of brake discs. Therefore, the production process must be 100% optimised. In this application, two distinct types of bores must be drilled and completed in the shortest possible of time.

| Workpiece | brake disc |

Bore number 1

| Bore | core bore for M8 thread |

| Chamfer | front and back: Ø8.5 mm x 90° |

| Material | cast |

Bore number 2

| Bore | Ø8.6 mm |

| Countersink forward | Ø17.2 mm x 90° |

| Chamfer backward | Ø0.5 mm x 45° |

| Material | cast |

Bore 1

Core bore is drilled in a single pass with a VEX drill combination tool and chamfered both front and back (Ø8.5 mm x 90°).

| Tool | VEX drill combination tool |

| Drilling working speed | 3,200 rpm. |

| Drilling working feed | 0.25 mm/rev. |

| Chamfering working speed | 1,900 rpm. |

| Chamfering working feed | 0.15 mm/rev. |

| Coolant | dry |

| Service life | > 30,000 bores |

Bore 2

In a single pass, this bore is drilled, then countersunk forward (Ø17.2 mm x 90°), and back chamfered (Ø0.5 mm x 45°). It is made with a special VEX drill and countersink combination tool.

| Tool | VEX drilling and chamfering combination tool |

| Drilling working speed | 2,600 rpm. |

| Drilling working feed | 0.26 mm/rev. |

| Drilling service life | > 30,000 bores |

| Chamfering forward working speed | 1,500 rpm. |

| Chamfering forward working feed | 0.15 mm/rev. |

| Chamfering forward service life | > 15,000 bores |

| Chamfering backwards working speed | 1,500 rpm. |

| Chamfering backwards working feed | 0.15 mm/rev. |

| Chamfering backwards service life | > 30,000 bores |

| Coolant | dry |

The integration of multiple machining operations in a single tool, combined with proven process capability, ensures the best possible cost efficiency.