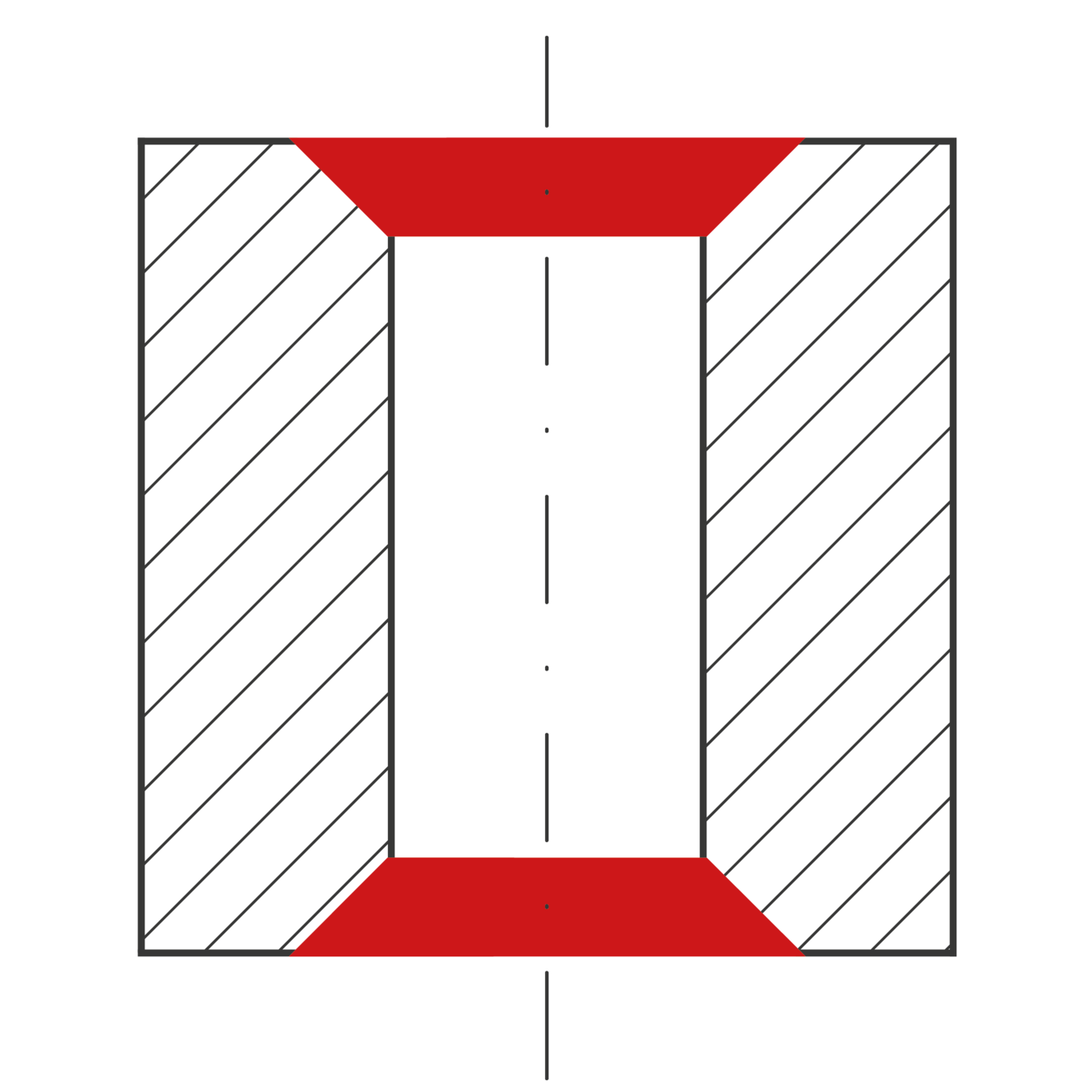

Mangueta

Mayor eficacia gracias a la solución de chaflanado de HEULE.

La tarea de esta mangueta para la industria automovilística es achaflanar varios orificios sin tener que repetir la sujeción hacia delante y atrás de la pieza en una sola operación.

| Pieza | Mangueta |

| Ø orificio | varios |

| Ø avellanado | varios |

| Material | Fundición de aluminio |

Debido al tamaño del chaflán requerido, la precisión y el corte de esta aplicación, se eligió la herramienta de chaflanado DEFA.

| Herramienta | DEFA |

| Velocidad de corte | 1000 rpm |

| Avance/vuelta | 0,06 mm/rev |

| Refrigerante | Emulsión |

La rentabilidad de la solución es primordial. Los tiempos de ciclo y producción sin parada del husillo, el cambio de sentido de rotación, interpolación y sujeción de la pieza fueron más reducidos que otros procesos de producción.