La produzione di fori e lamature nei cerchi in alluminio richiede oggi l’impiego di quattro diversi utensili. Il piano operativo richiede inoltre una rotazione del pezzo. Le spese di riparazione e il relativo tempo di inattività per la regolazione degli utensili riparati sono considerevoli. I costi elevati degli utensili esistenti e l’affidabilità di processo non garantita sono stati un motivo sufficiente per ripensare l’attuale sequenza di produzione.

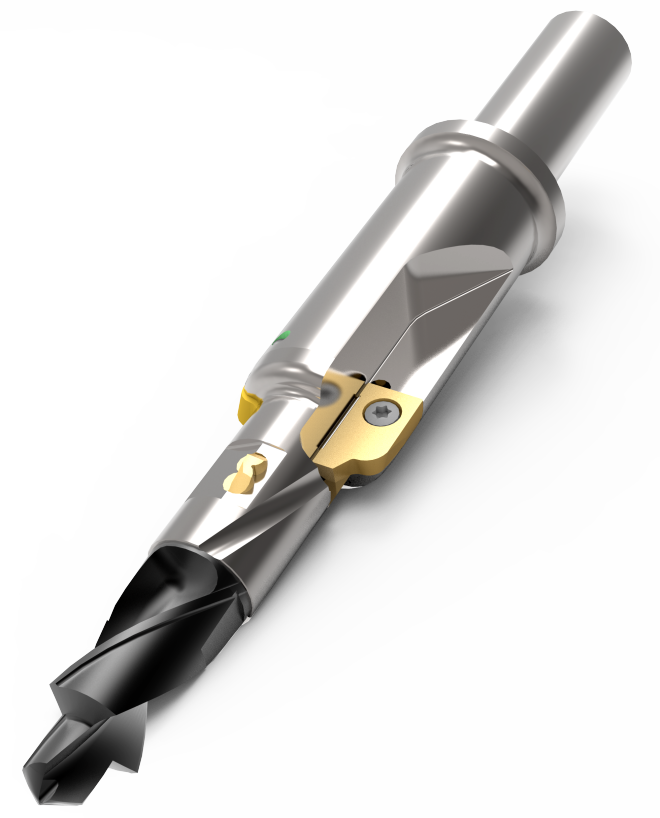

La soluzione di HEULE prevede di riunire tutti e quattro gli utensili esistenti in uno solo. A questo scopo, HEULE fonde due sistemi di utensili esistenti e ne combina i vantaggi in modo ideale. Il nuovo utensile rende superflua la dispendiosa rotazione del pezzo.

| Utensile | Foratura-lamatura Utensile combinato |

| Corpo utensile | VEX-SNAP5 versione speciale |

| Lama | SNAP5 Ø11.6 DLC /GH-Q-M-15547 per taglio solo in tirata |

| WSP | Piastra 30° rivestita di metallo duro |

| Parametri di taglio di foratura | Velocità: S = 2.750 giri/min. Avanzamento: F = 550 mm/min. |

| Parametri di taglio di smussatura | Velocità: S = 2.750 giri/min. Avanzamento: F = 450 mm/min. |

Il cliente è molto soddisfatto del risultato e del risparmio di tempo ottenuto. In queste applicazioni con più operazioni in un unico utensile è importante adattare l’avanzamento e la velocità per la lamatura e la smussatura. Il raffreddamento interno è assolutamente necessario per l’eliminazione dei trucioli. HEULE sceglie un design utensile il più stabile possibile, in modo che non si verifichino vibrazioni. Lo spazio disponibile costituisce il quadro di riferimento per il dimensionamento dell’utensile speciale combinato. Gli utensili speciali HEULE sono noti per la loro semplicità e affidabilità di processo.