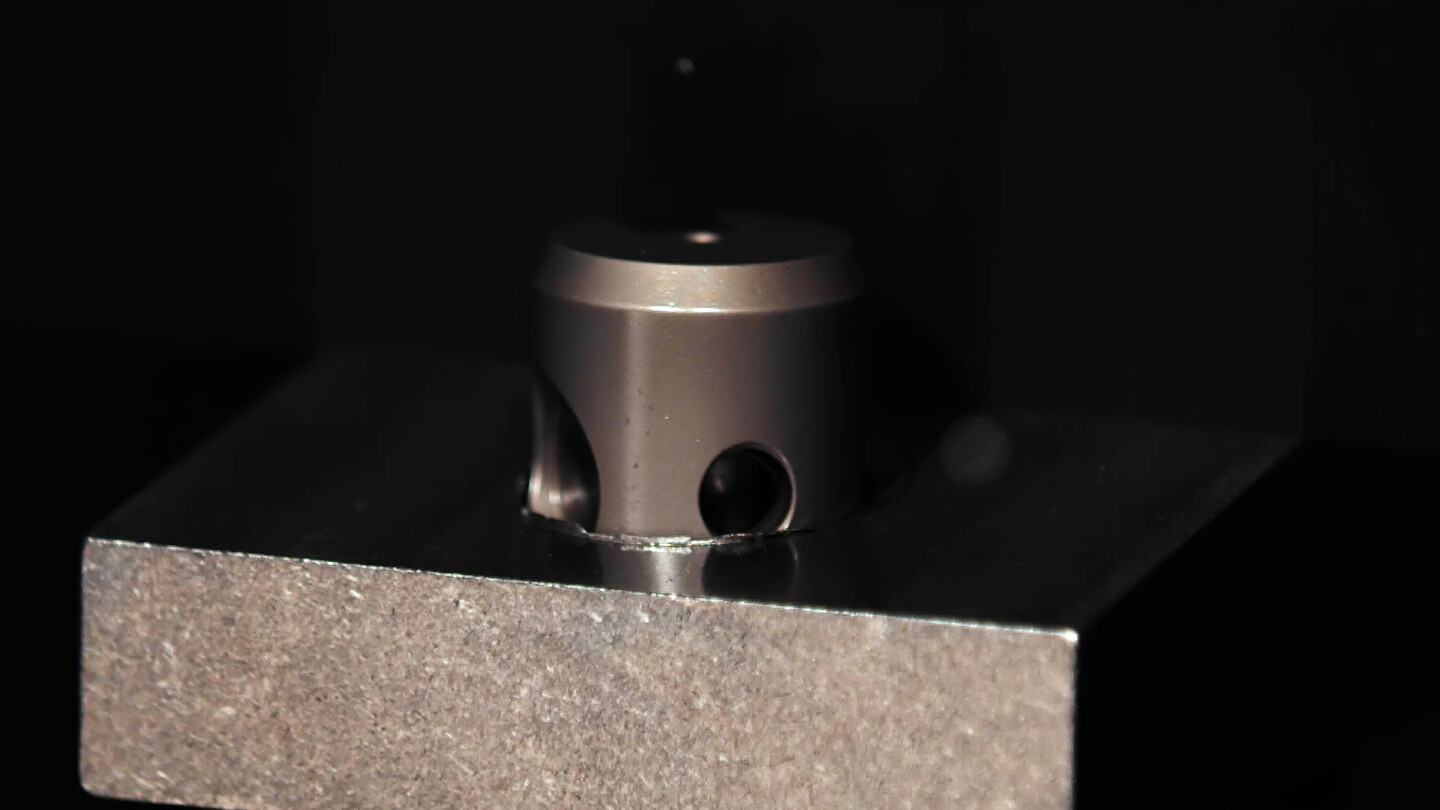

In primo piano: retro del foro.

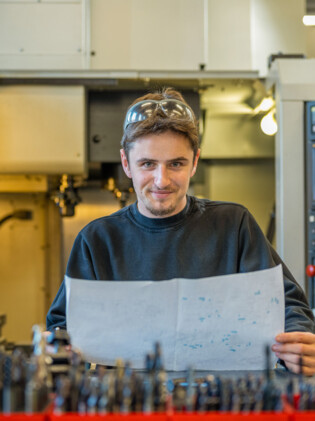

Per una lavorazione in tirata e spinta in un’unica operazione!

Processi estremamente efficienti e sicuri per il vostro successo.

Sbavatura uniforme in tirata e spinta in un’unica operazione, senza rotazione del pezzo.

Vai alle soluzioni

Convenienza nelle attività di smussatura di fori in tirata e spinta in un’unica operazione.

Vai alle soluzioni

Retrolamatura dei fori senza rotazione del pezzo.

Vai alle soluzioni

Convenienza nelle attività di foratura in combinazione con sbavatura, smussatura o lamatura.

Vai alle soluzioni