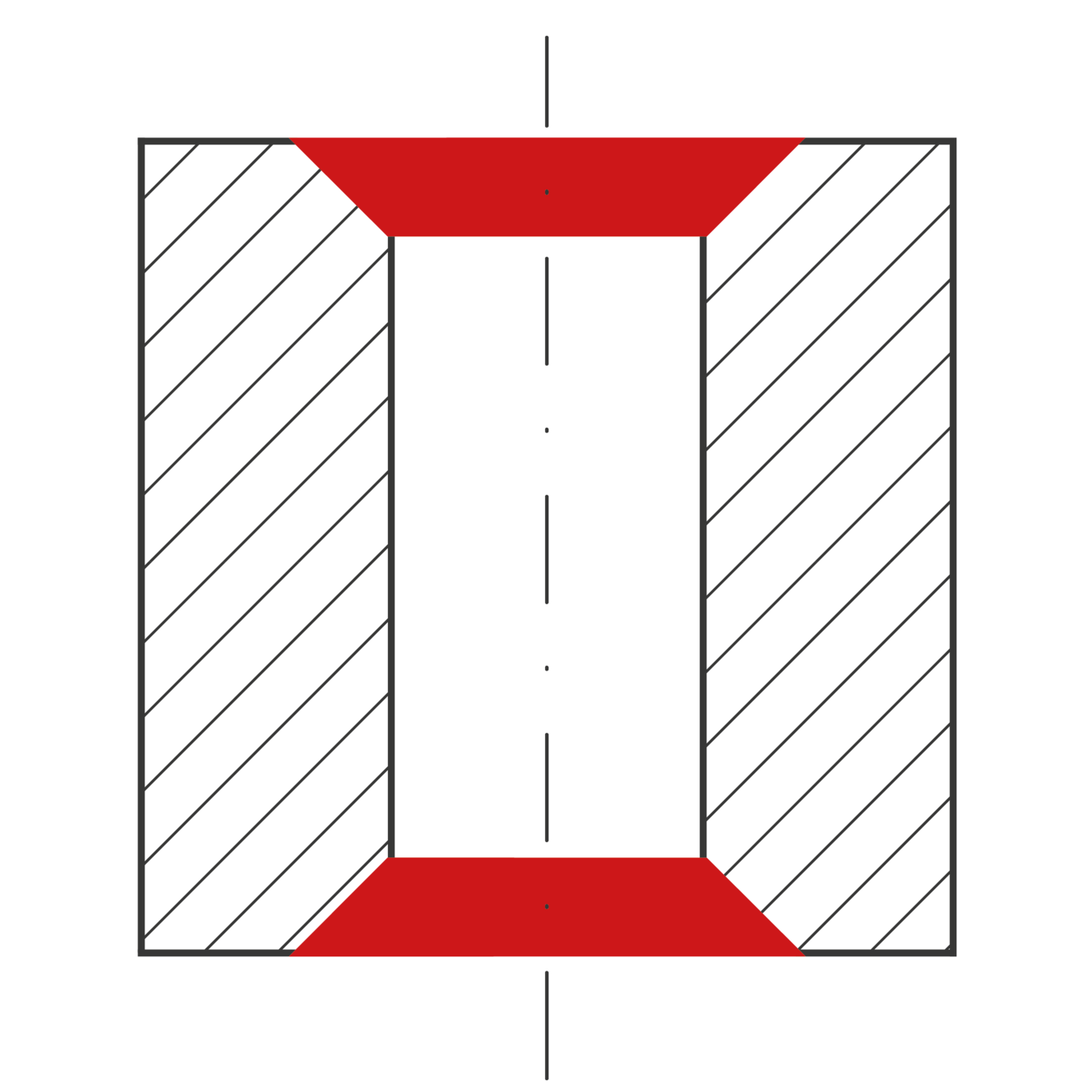

Turbine Rotating Part

Automated chamfering in one operation. Minimisation of tool changes, elimination of manual deburring.

The customer was looking for an automated solution to machine chamfers to bores front & back in one operation. The goal was to minimise tool changes and process time as well as eliminate manual deburring.

| Workpiece | Aviation component |

| Material | 17-4 PH Steel |

| Parts per year | 50 parts (1’000 bores) |

HEULE recommended a SNAP tool for front and back bore chamfering. It allowed chamfering front and back with one tool. Manual deburring was eliminated. HEULE helped to reduce process time to an absolute minimum.