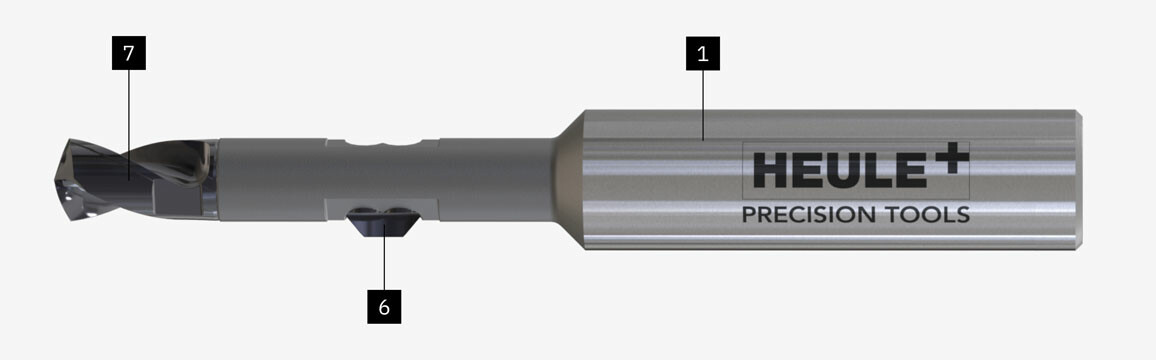

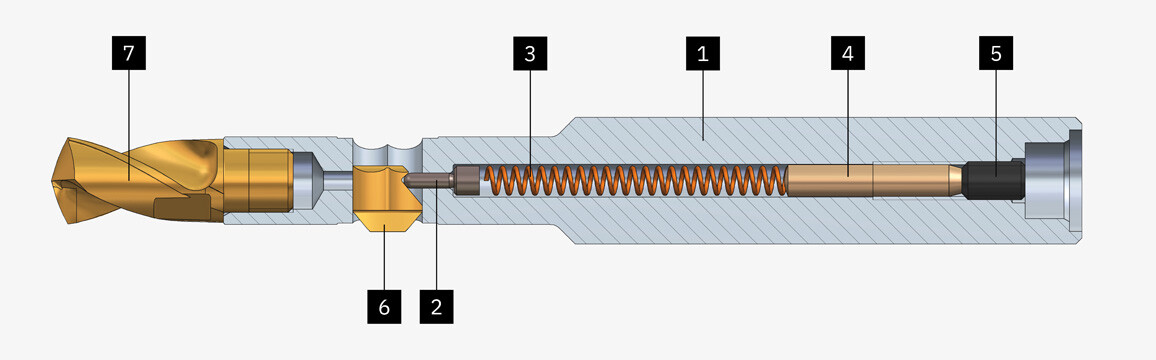

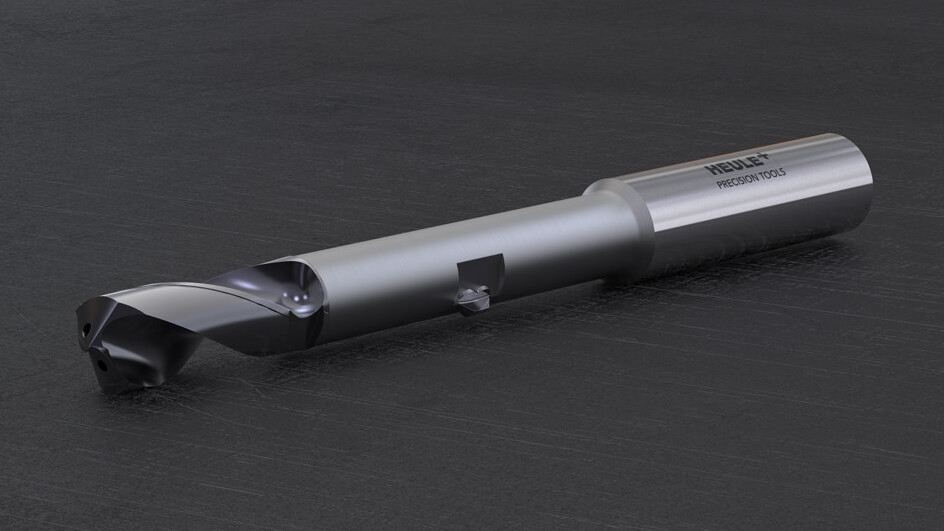

VEX

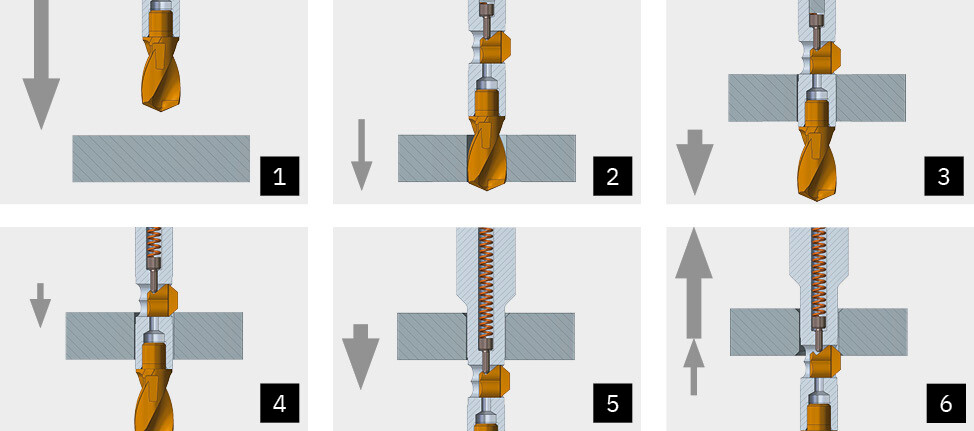

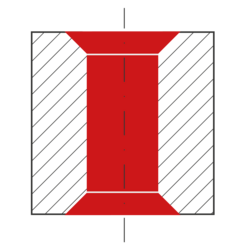

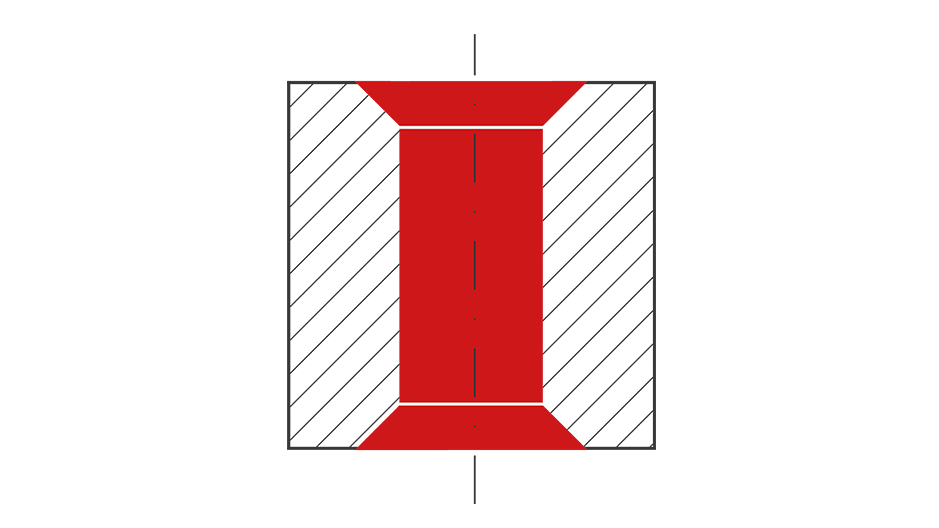

Drilling combined with front and back chamfering in a single pass

- Bore diameter 5.0 mm – 17.0 mm, drilling depth up to 2xd

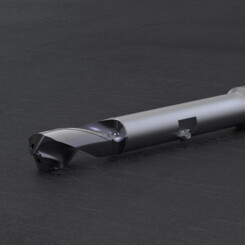

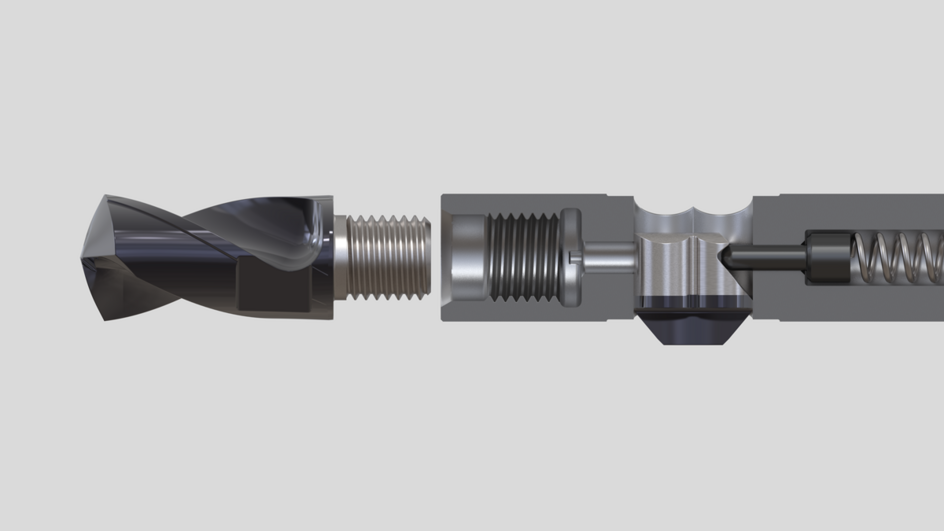

- Easy-to-change carbide twist drill insert or drill head.

- Internal coolant possible from bore Ø 6.0 mm

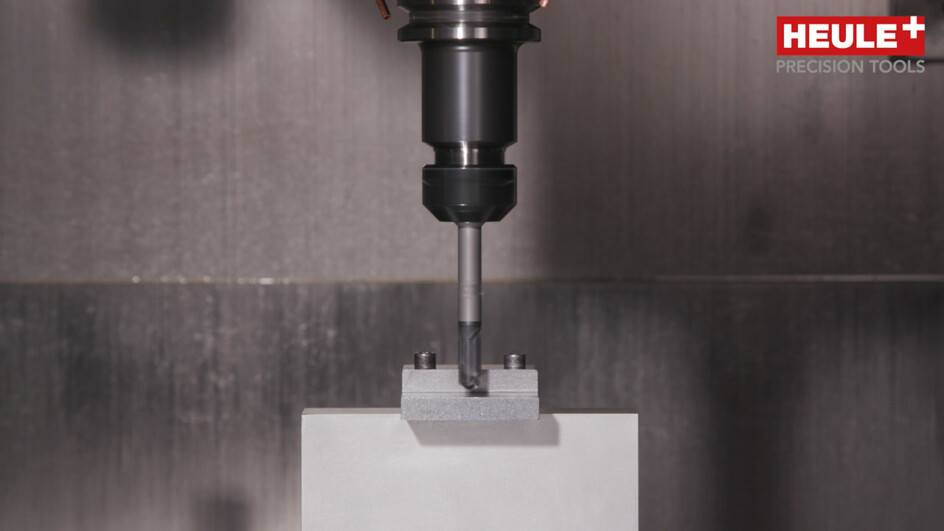

- Short set-up and reduction of idle times thanks to simple handling

- Reduced process times thanks to multifunctional processing in a single tool