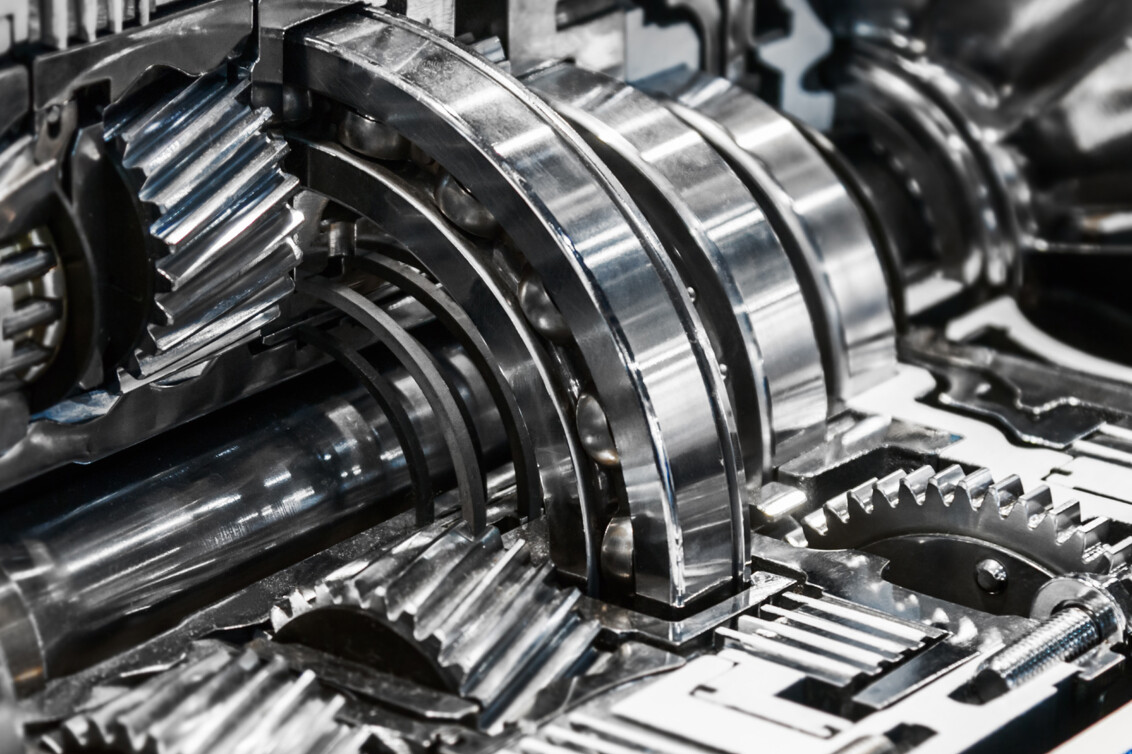

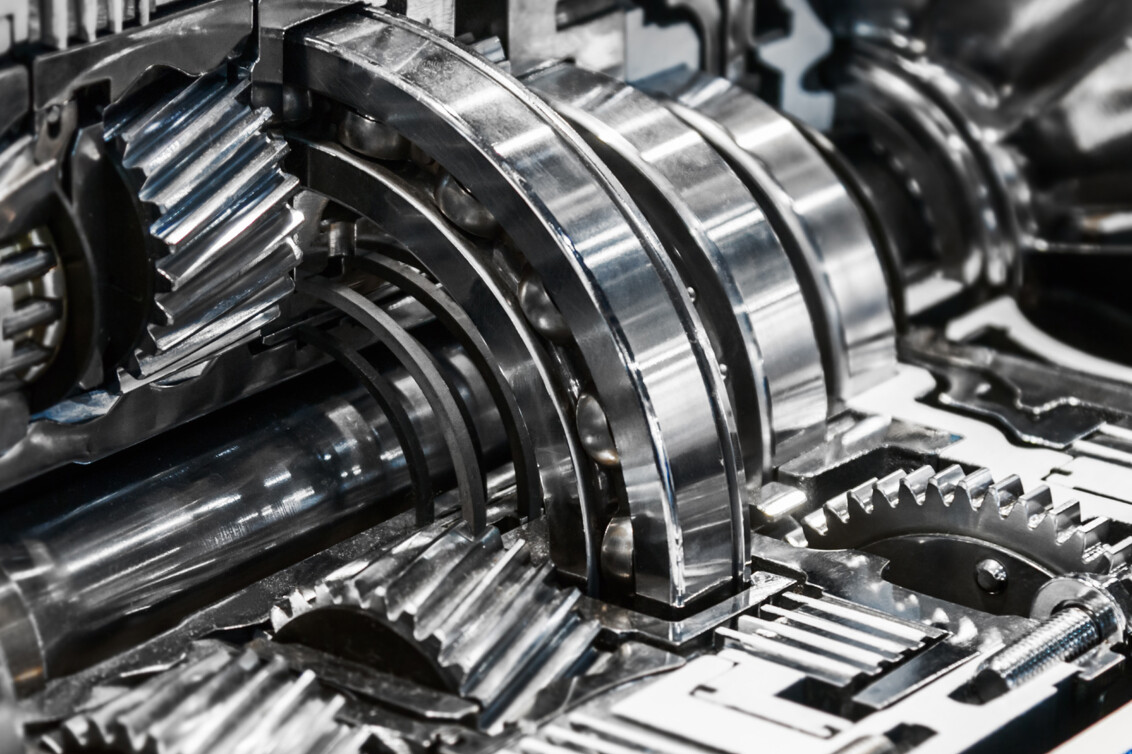

Shell ring connector

Drilling, forward and backward chamfering simultaneously: Cost reduction of more than USD 100,000 per year.

This gearbox manufacturer had to drill and deburr a shell ring with 12 bores in the most efficient way.

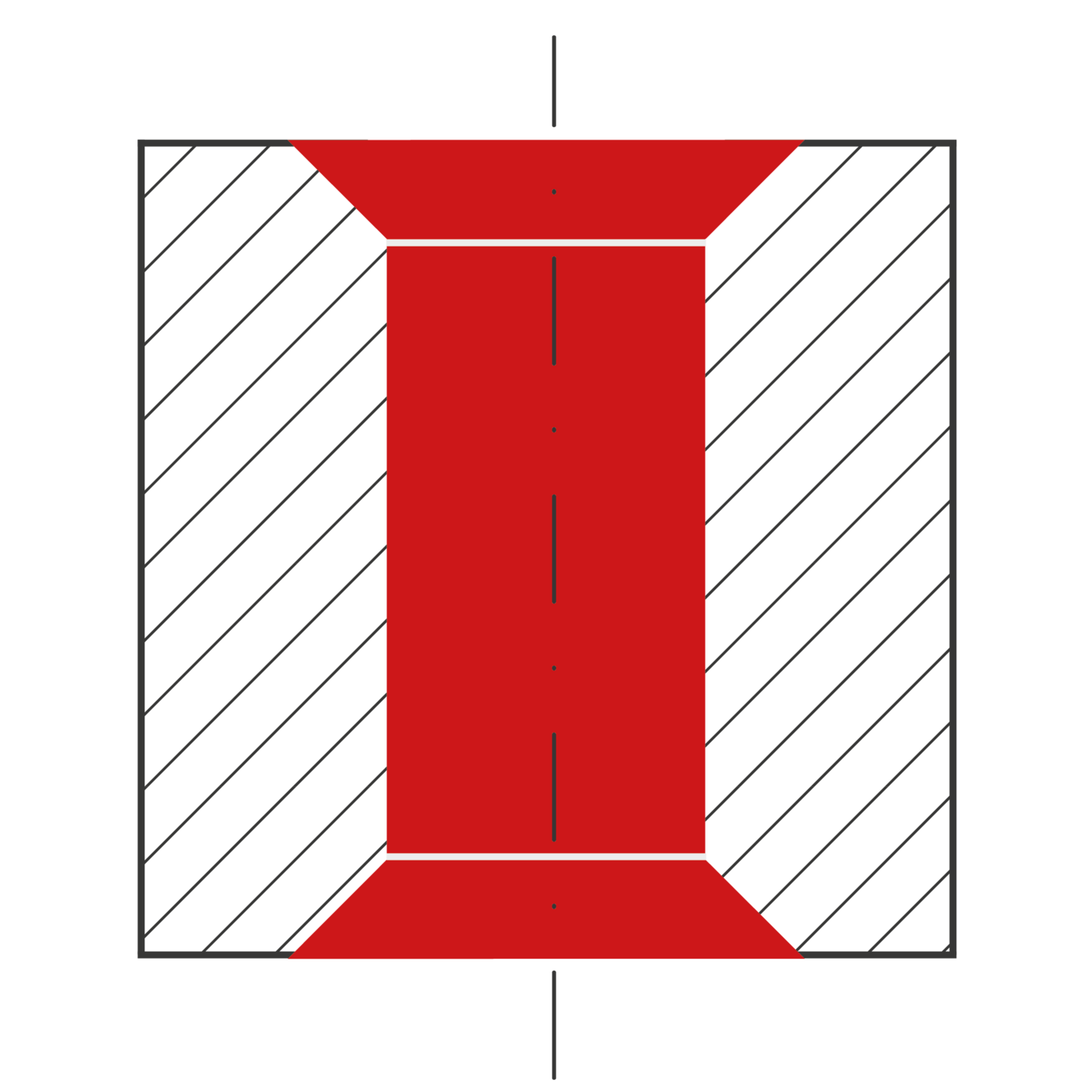

| Workpiece | Shell ring connector |

| Bore | Ø5.0 mm |

| Material thickness | 4.0 mm |

| Material | ADC 10 |

| Machine | Magnix tapping centre |

| Volume | 1 million workpieces per year |

HEULE recommended its combined drilling and chamfering tool VEX 5.0 (GH-QO-4000) with SNAP technology. The bore is first drilled, followed by the chamfering of the front and back bore edges.

| Tool | VEX |

| Drilling speed | 6'200 RPM |

| Drilling working feed | 0.2 mm/rev |

| Chamfering speed | 738 RPM |

| Chamfer working feed | 0.15 mm/rev |

| Coolant | external coolant |

This solution offers significant processing time savings by combining three process steps in a single pass. With the switch to VEX, the gearbox manufacturer eliminated two CNC machining centre.