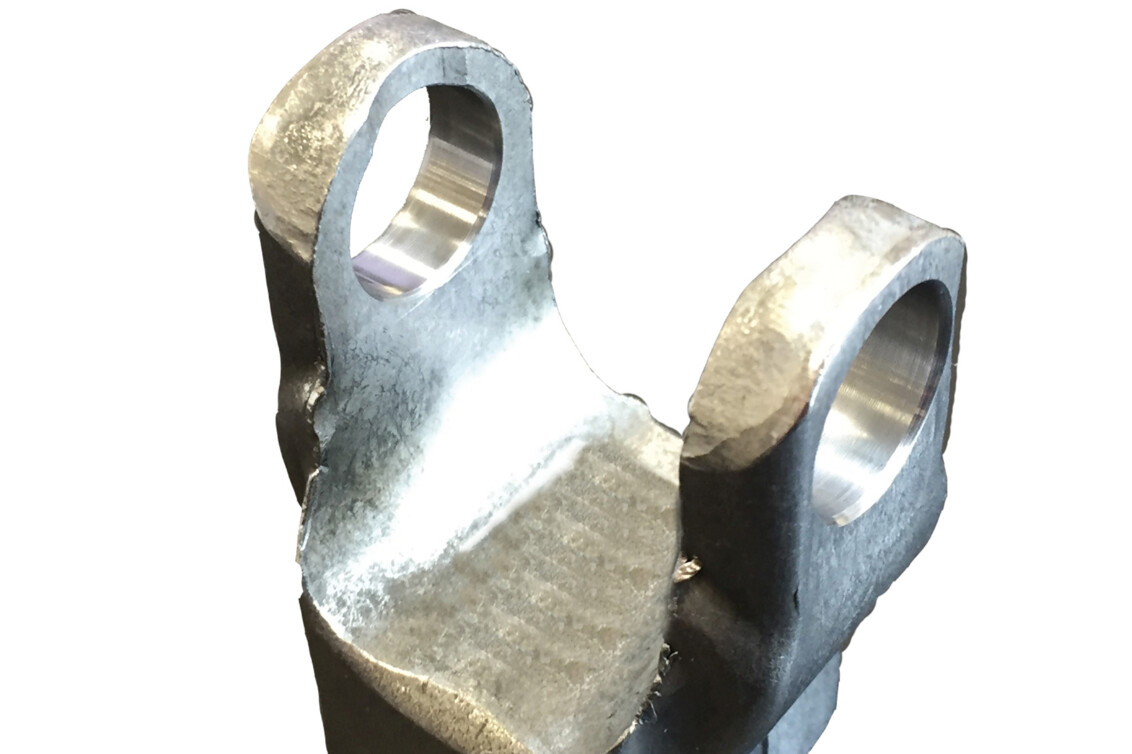

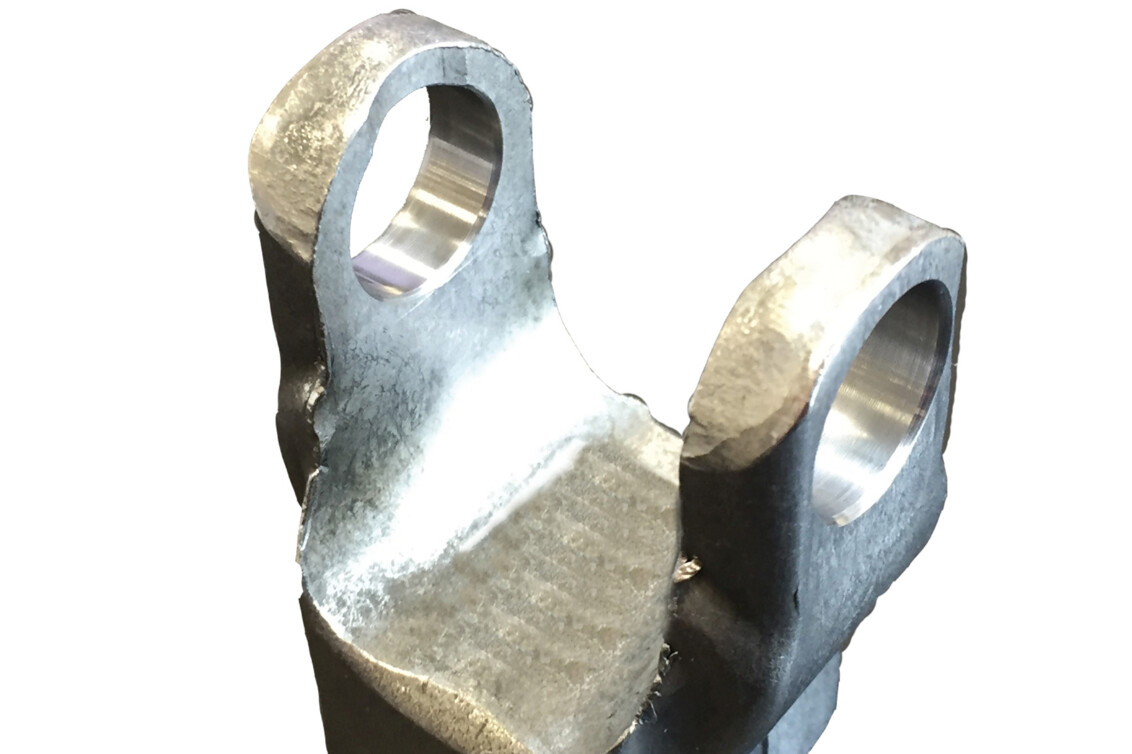

A Swiss supplier for the German automotive industry was previously required to manually deburr the fork, used in a steering column. Faced with the problem that manual deburring was too time-consuming and caused a production backlog, the company was looking for a new solution.

| Workpiece | Fork piece |

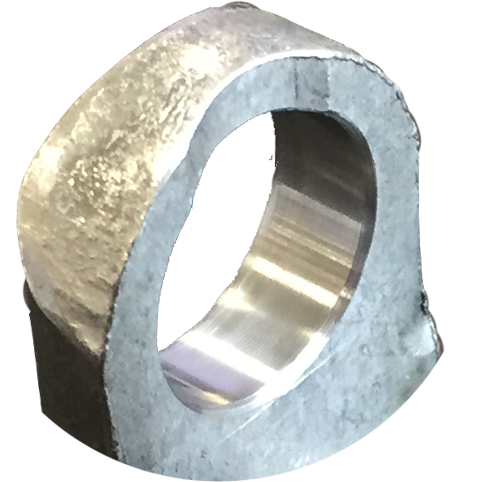

| Bore Ø | 15.0 mm |

| Deburr size | max. 0.3 mm |

| Material | steel |

| Machine | Hermle Milling Centre |

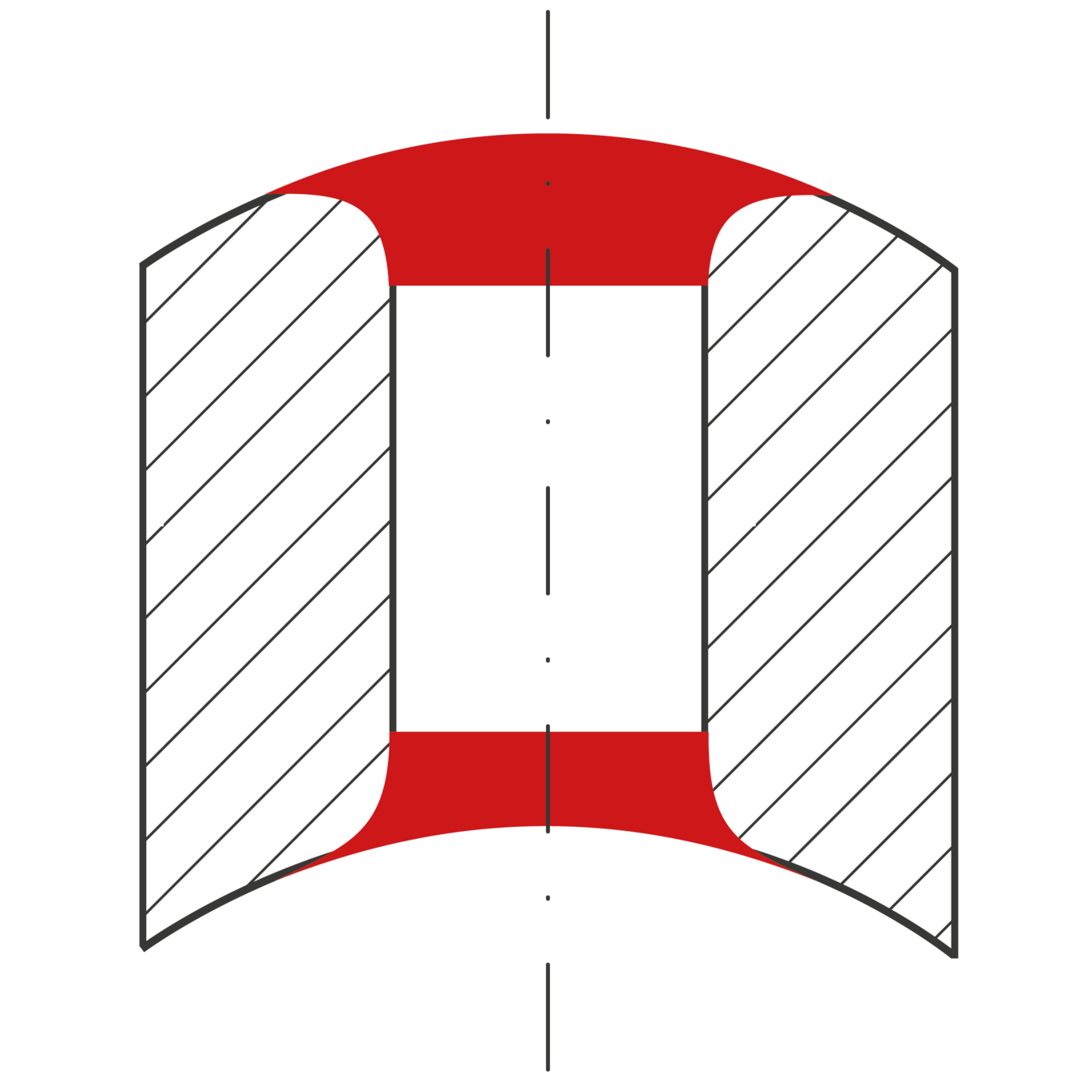

| Machining | axial |

| Coolant | external coolant, 30 bar pressure |

| Dimensions | d = 15.0 mm, H = 42.0 mm, E = 28.0 mm |

| production volume | 200'000 bores per year |

Fork piece deburring is a tried and tested application of the COFA tool. Customer requirements to minimise processing cycle time as much as possible led to the development of a unique solution. The 15.0 mm diameter could also be machined using a standard COFA tool. HEULE proposed a double-cassette tool in order to work with a maximum working feed rate. This tool uses two blades.

| Tool | Double cassette toolCOFA C6 |

| Blade | C6-M-0006-T |

| Speed | 1,000 rpm |

| Working feed | 0.8 mm/rev |

The customer defines the benefit as the elimination of manual rework and the now process-reliable deburring, i.e. the time savings. But the emphasis is on the thrilled machine operator, who no longer has to manually process the parts.