Aircraft component

The replacement of the manual chamfering process has reduced production time.

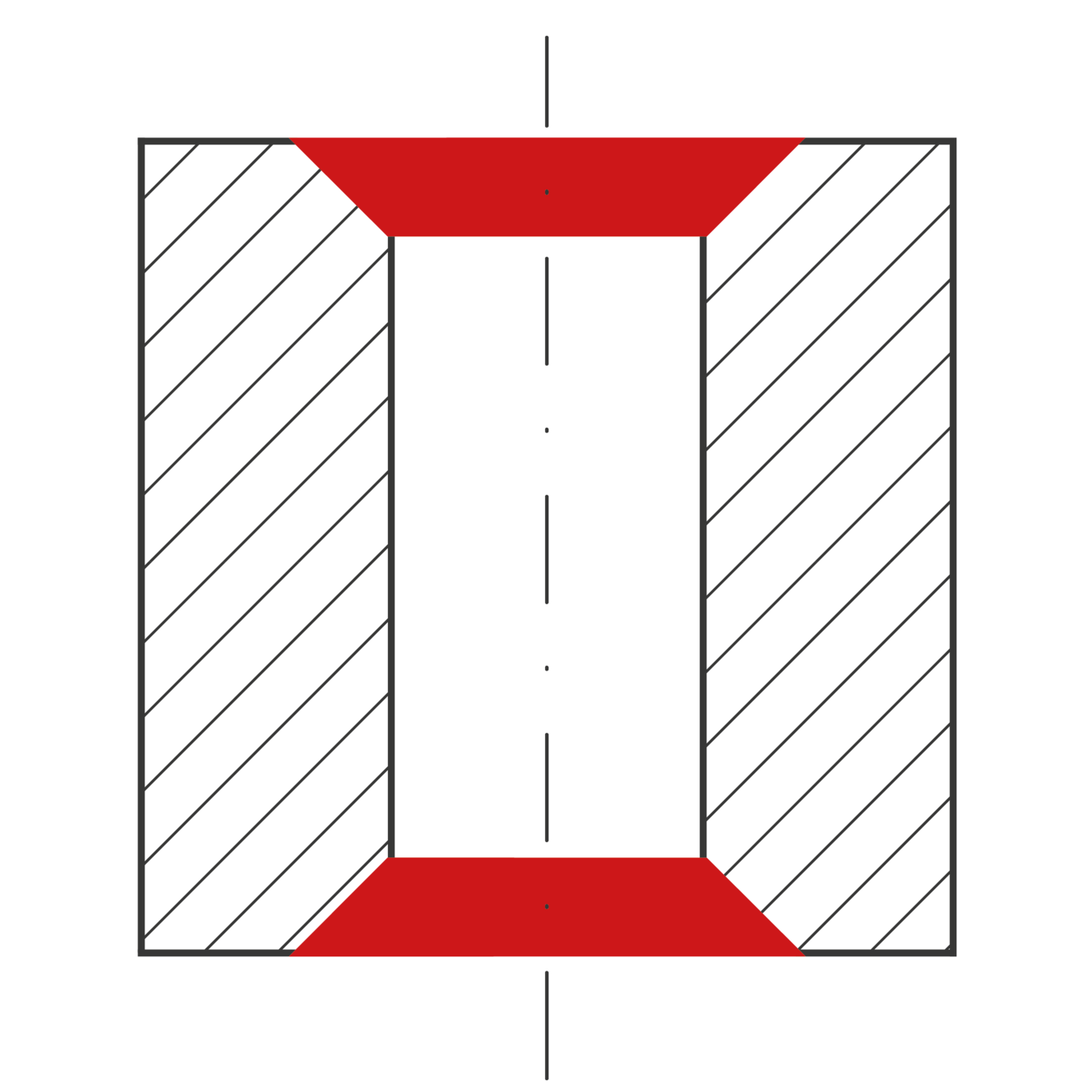

Previously, because of poor accessibility, the front and back chamfer of the bores had to be performed manually. This caused issues with adhering to the high aviation industry standards and caused long production cycles.

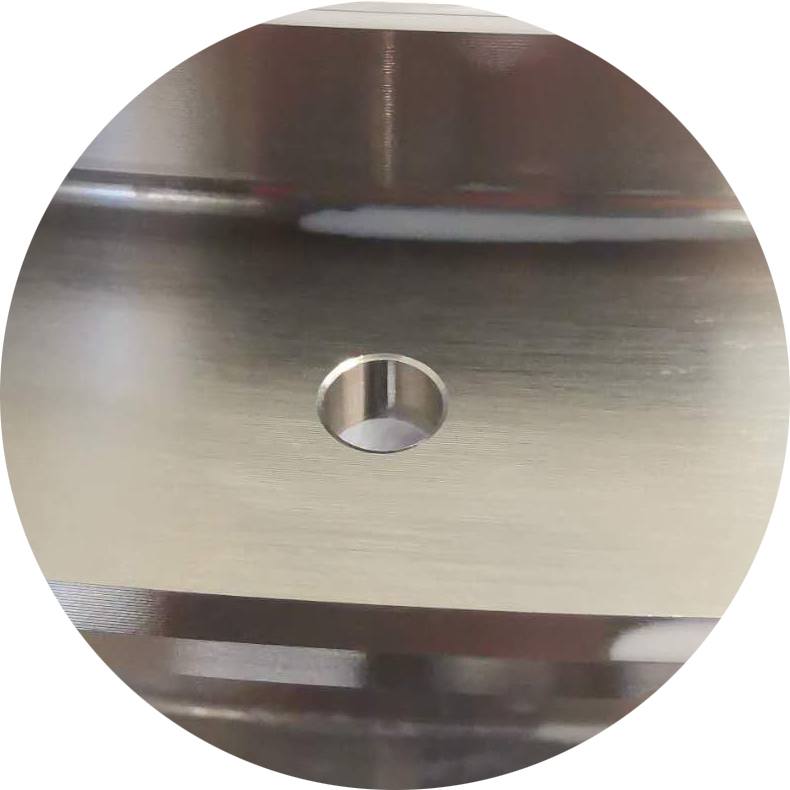

| Workpiece | Aviation component |

| Bore diameter | Ø7,036 mm |

| Material | Inconel 718/718plus |

| Machine | Vertical/Horizontal Machining Centre |

This solution was accomplished with the DEFA chamfering tool (two-bladed) which assures highest quality and guarantees process-reliability. The parts can now be completed entirely on the CNC machine without the need for further manual chamfering.

| Tool | DEFA 7.0-8.0/34 (GH-SD-5214) |

| Blade | DEFA 7.0-8.0 (GH-SM-3909) |

| Cutting speed | 400 RPM |

| Working feed | 0.08 mm/rev |

The customer achieved the following improvements: