Aircraft Component

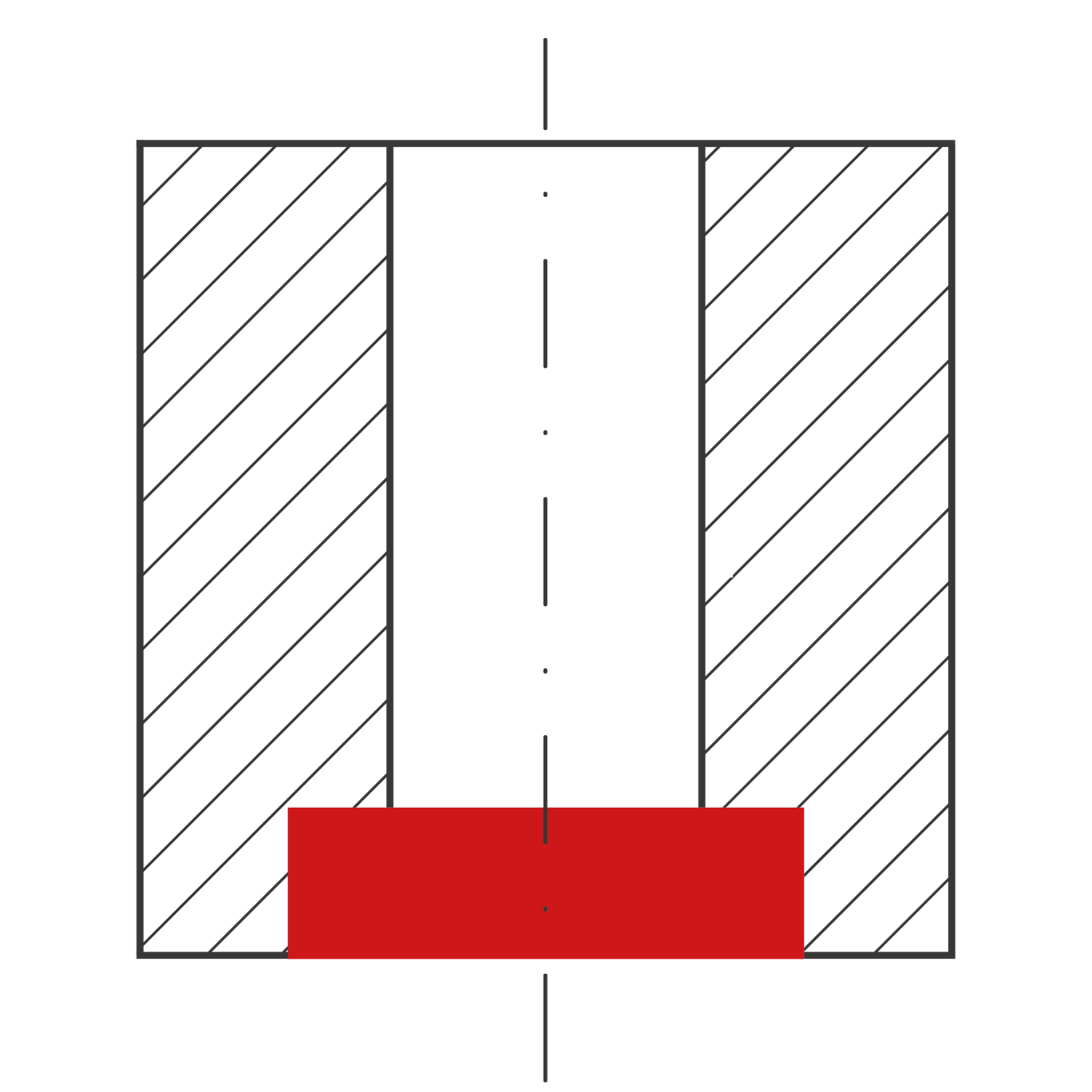

Massive reduction in process time through back bore machining.

Our customer previously created 30 back spotfacings by turning the part, re-clamping and machining them from the other side. This process took over six hours. The goal was to simplify the operation and to speed up the process

| Workpiece | Aircraft component |

| Material | Inconel 718 Cast |

| Parts per year | 50 workpieces (1’500 bores) |

The BSF tool allows reliable operation from one side, eliminating the need to re-clamp the housing. Process time decreased from 6 hours to 35 minutes per part.