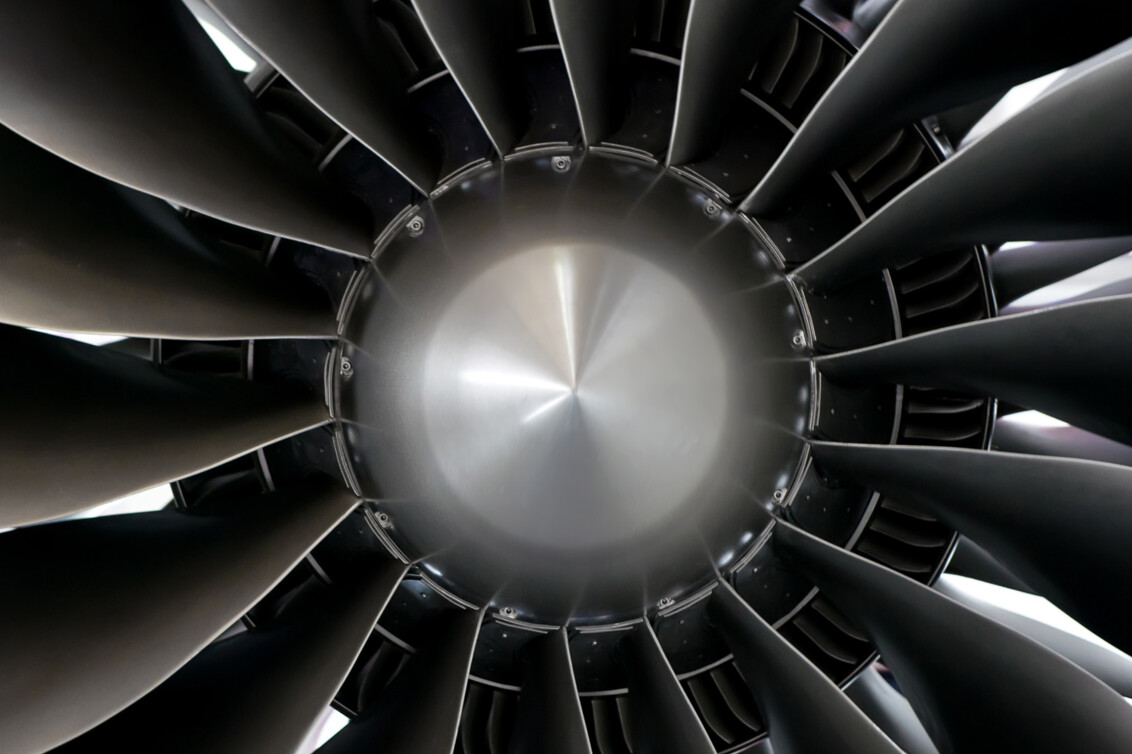

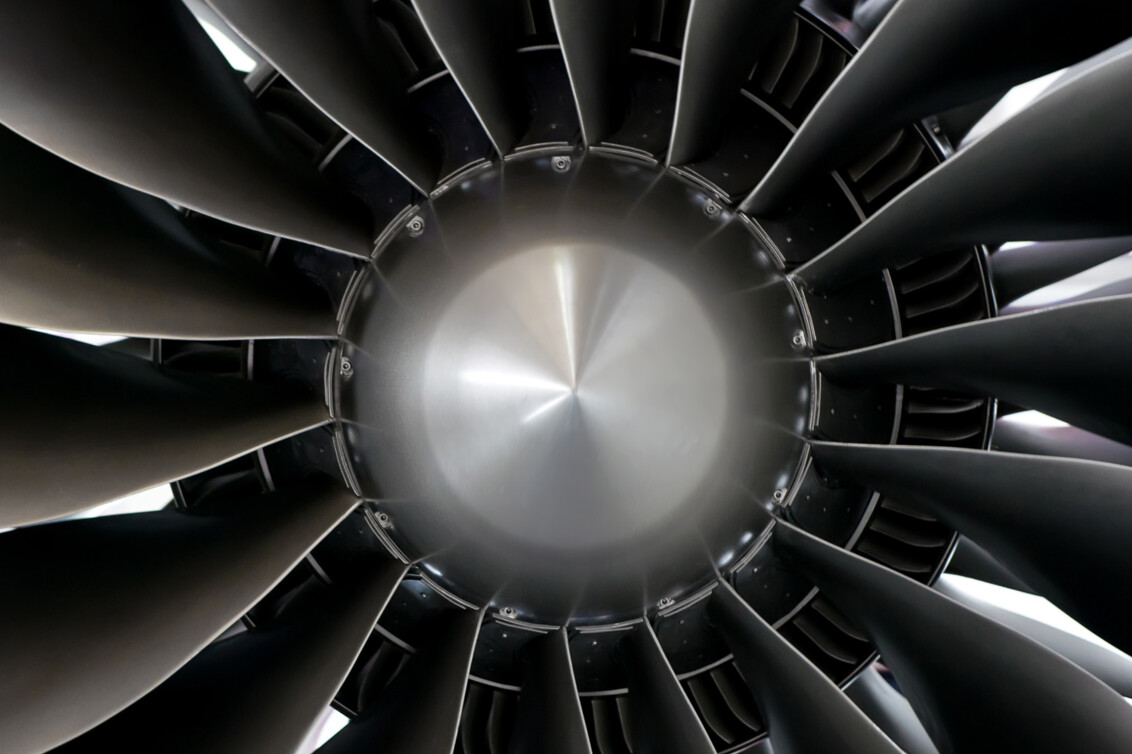

Low pressure turbine stator housing

75% reduction in machining time per bore.

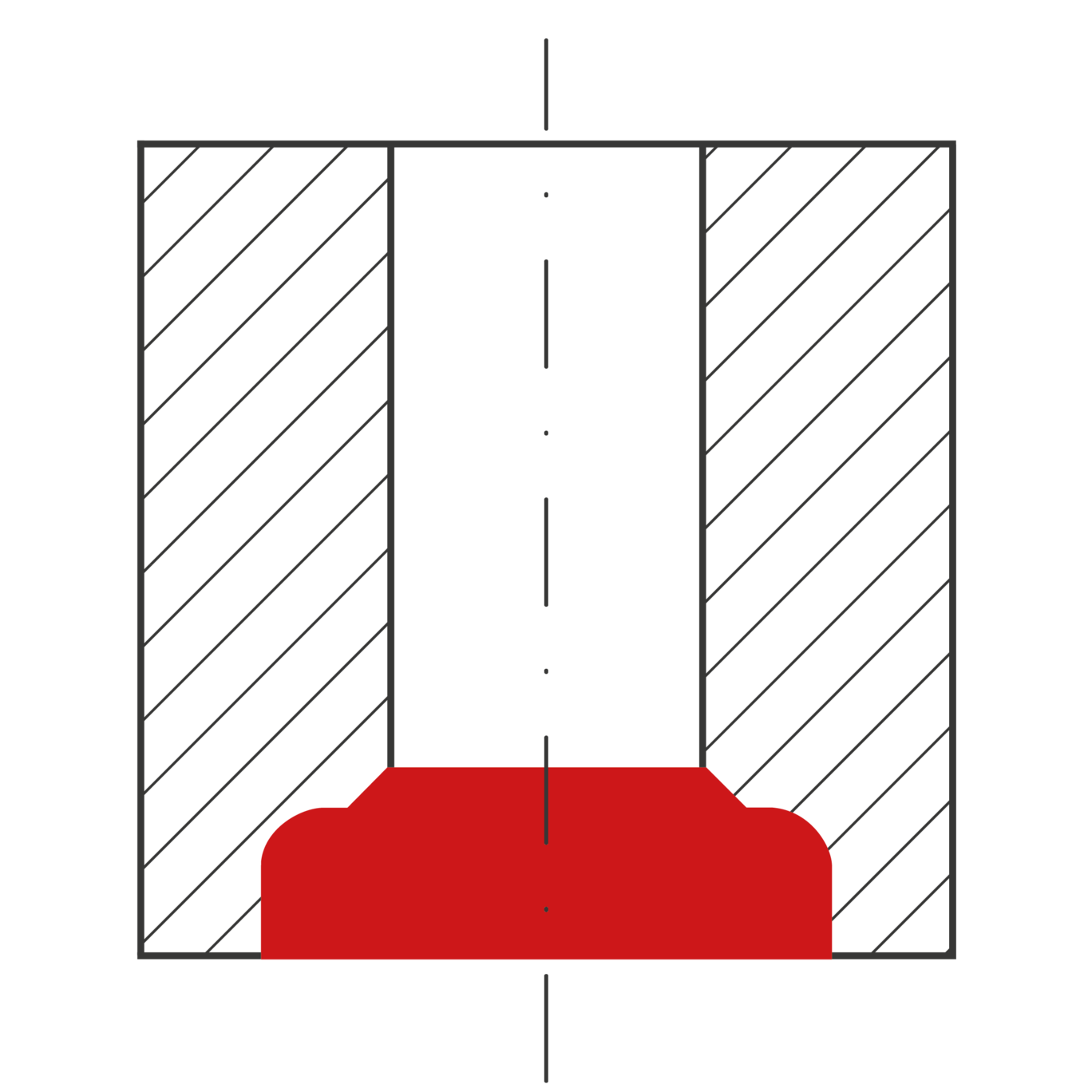

The previous process required machining of the counterbore from two sides. Additionally, chamfering had to be done manually. Overall, the process was time consuming and cumbersome.

| Workpiece | Low pressure turbine stator housing |

| Bore | Ø7 mm |

| Counterbore | with chamfer on the inner bore edge / Ø13 mm |

| Cut | partially interrupted |

| Material | Inconel 718 |

| Material thickness | 4.0 mm |

| Machine | STARRAG STC1000 |

| Estimated production volume | 50 parts (3,200 bores) / year |

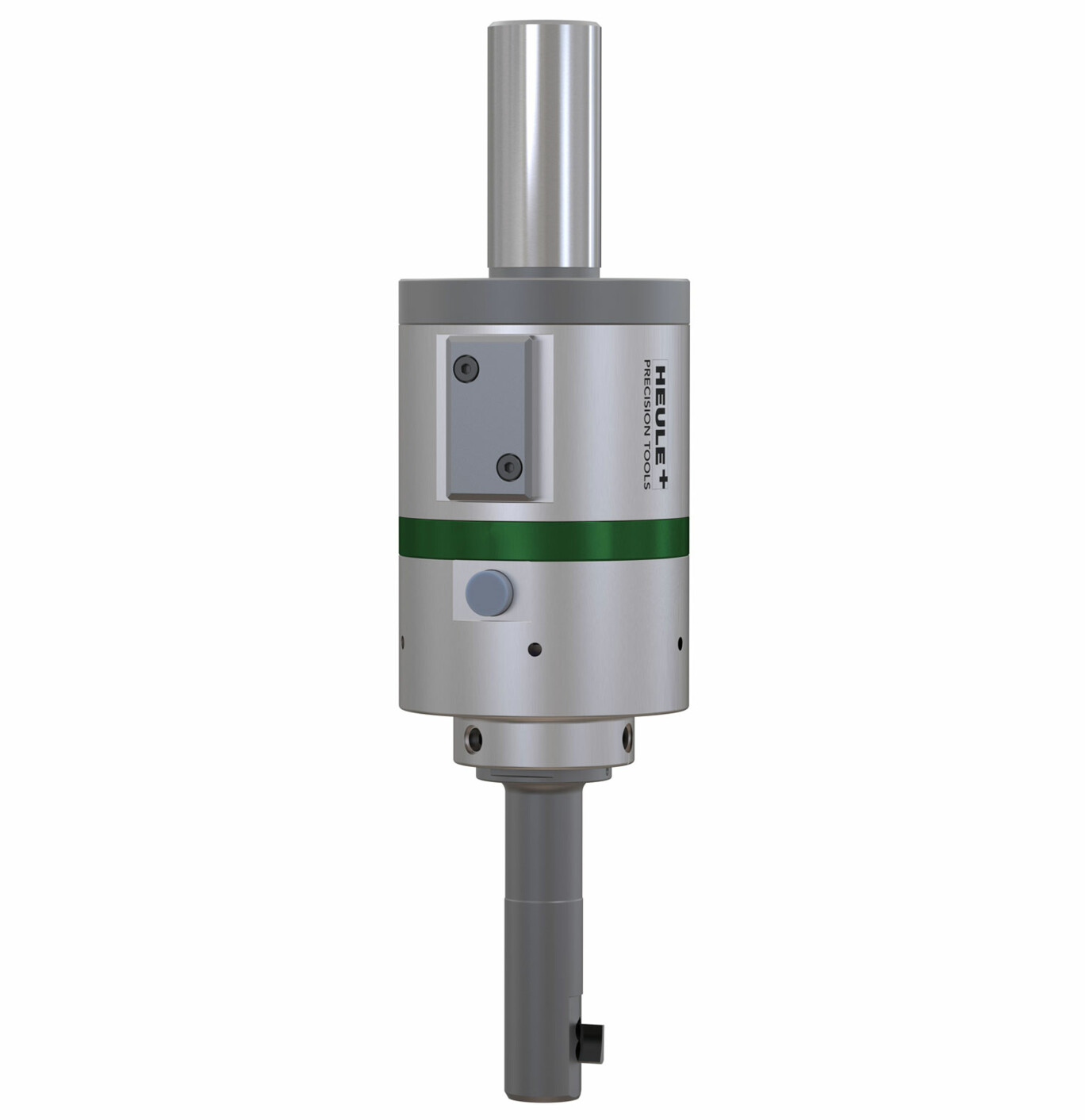

HEULE proposed its SOLO counterboring tool, distinguished by its ease of use and high production reliability. Thanks to the construction of a customer-specific blade that simultaneously applies a chamfer to the bore, the previously required additional deburring process is no longer needed.

| Tool | SOLO |

| Blade | application specific |

| Working speed | 1'900 RPM |

| Working feed | 0.03 mm/rev |

| Coolant | external coolant |