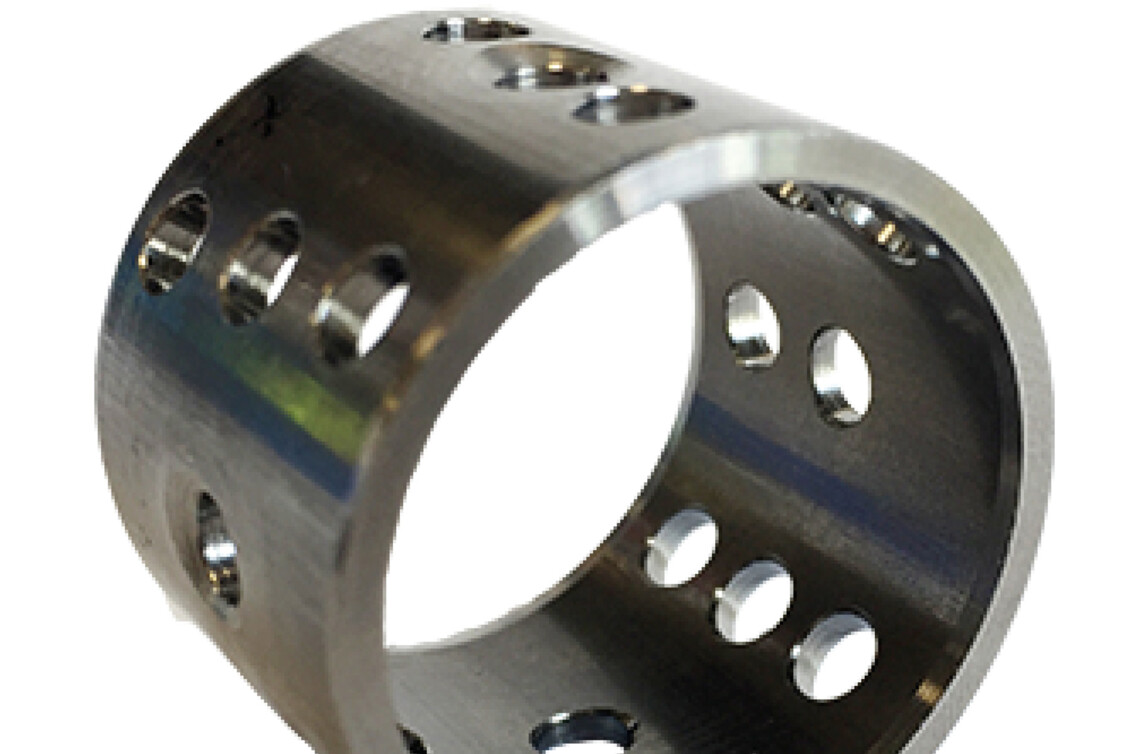

Bearing bushing

Cycle time improved by 20%.

This customer has to supply 400’000 bearing bushings per year. Four bores have to be machined into each bushing. The previous solution the customer used to deburr the bores was very slow, inconsistent and resulted in substantial manual rework.

| Workpiece | Bearing bushing |

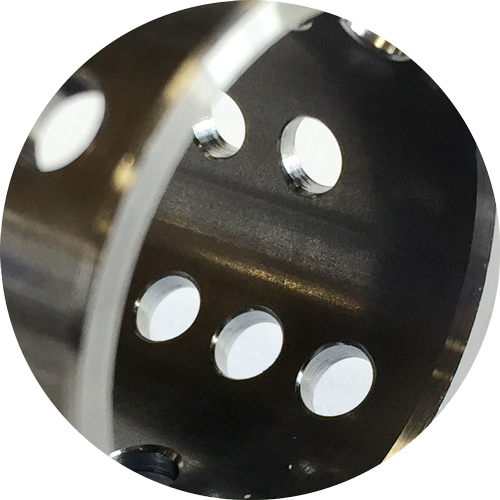

| Bore diameter | 4 mm |

| Outer Tube Ø | 30 mm |

| Inner Tube Ø | 26 mm |

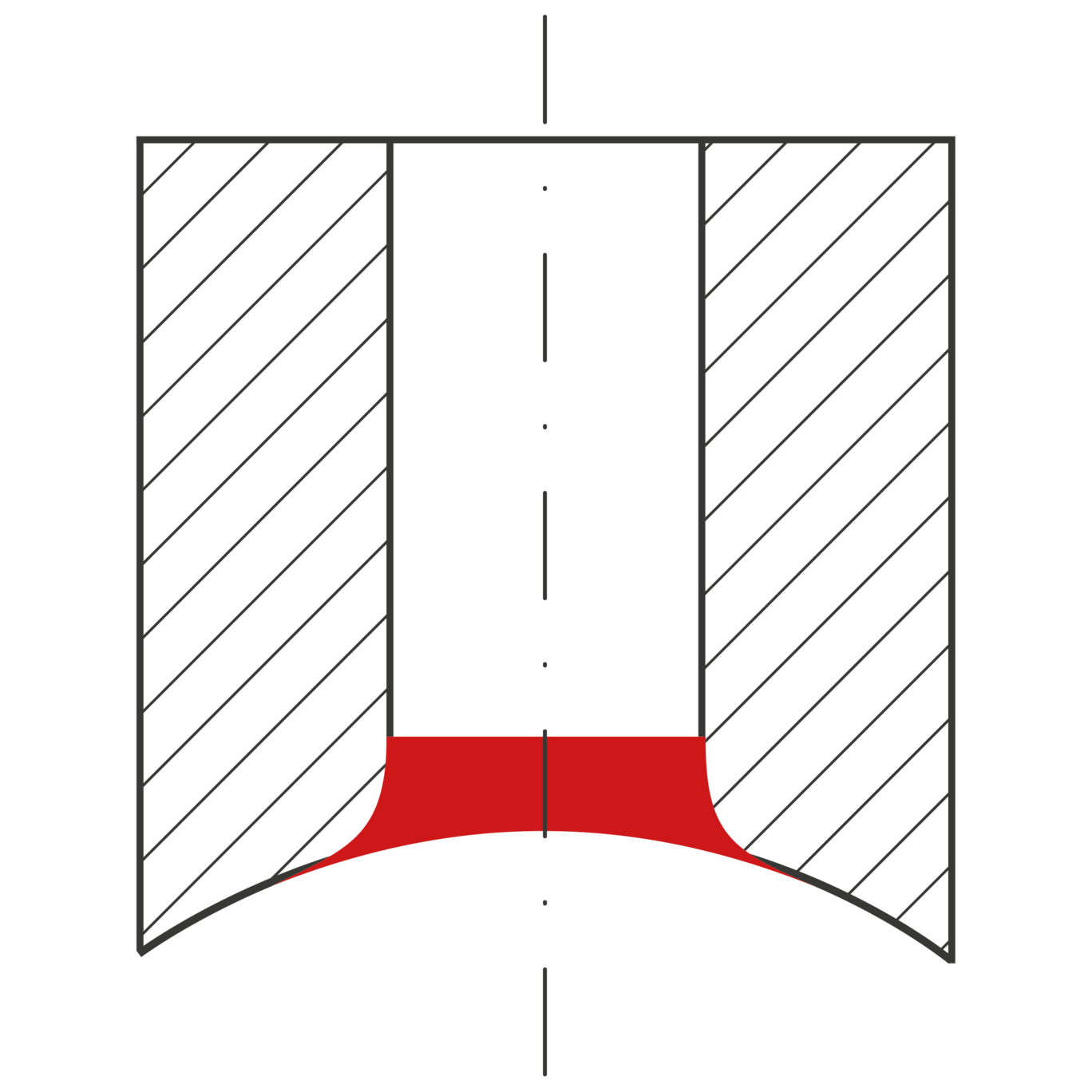

| Chamfer diam. burr free | max. 0.5 mm |

| Material | Steel / 1.0580 E 355 |

| Production volume | 1'600'000 bores per year |

| Machine | Long turning lathe |

| Processing | Radial processing from the bar |

| Coolant pressure | 30 bars |

The HEULE COFA deburring tool now used, increased cycle time by 20%, assures highest quality and process-reliability. No manual rework is required anymore.

| Tool | COFA4M/4.0/Z1-OM |

| Blade | GH-CM-0914-T nrs |

| Cutting speed | S = 1,200 rpm / v = 15 m/min |

| Working feed | f = 0.2 mm/rev (F = 240 mm/min) |

The deburring process is reliable, so the manual reworking is no longer necessary. The cycle time could be optimised, resulting in a minimum 20% improvement. Long-tenured employees with extensive expertise are as much excited about the result as the production manager, who can now rely on a process-safe solution.