The challenge for this Tier-1 supplier to the aircraft industry was to effectively machine eccentric counterbores Ø13, all from one side without the need to re-align and re-clamp the part in the machine. Due to the fact that the application is based on military specifications, the requirements are particularly high.

| Workpiece | Component with eccentric back spotfacing |

| Diameter of final bore | 8.3 +/- 0.2 mm |

| Diameter of counterbore | 13.0 +/- 0.2 mm |

| Material | Special steel with high strength and corrosion resistance that is difficult to machine. |

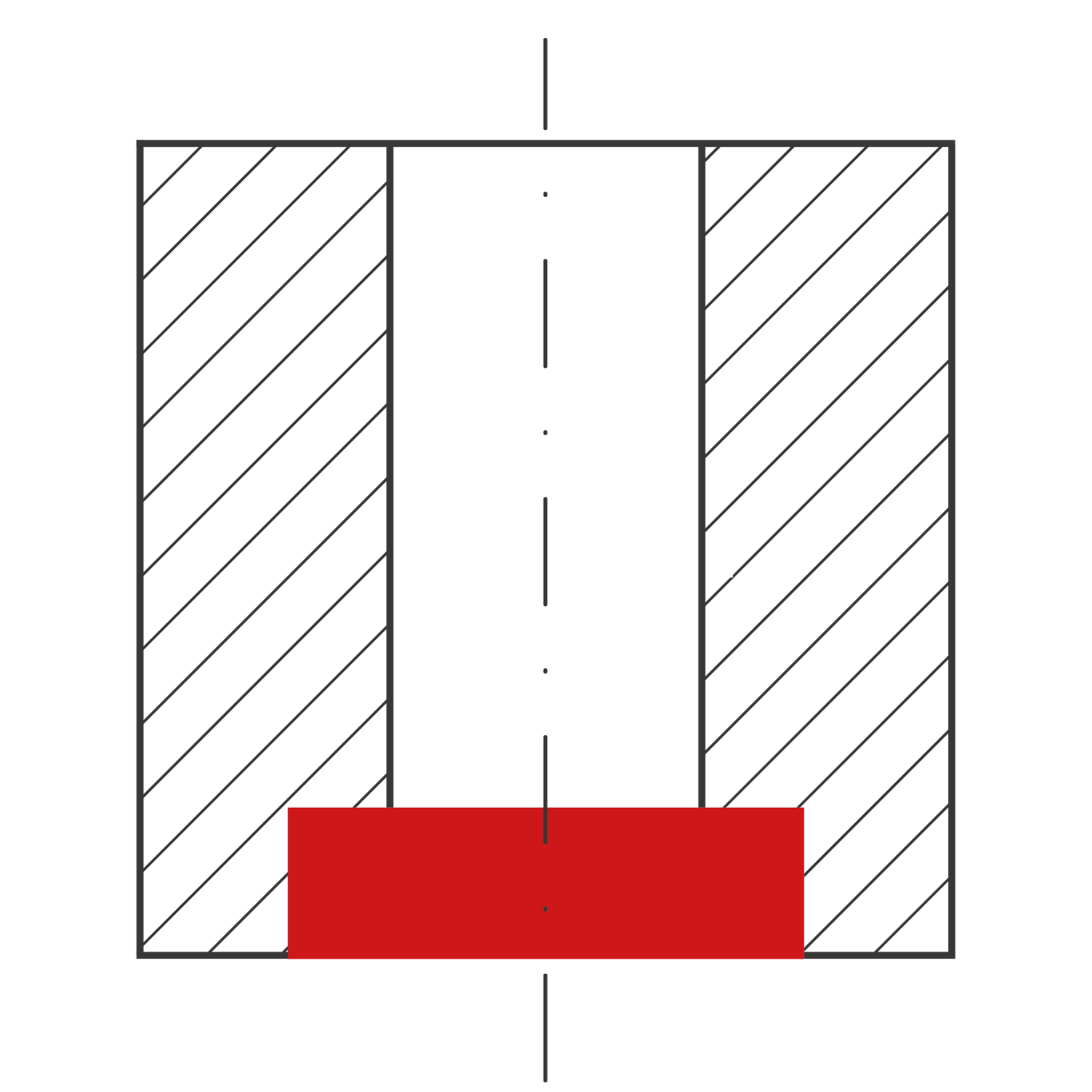

In order to realise the eccentric counterbores, temporary 6.35 mm pilot bores are drilled. The counterbore Ø 13.0 is then machined with a HEULE BSF tool before extending the pilot bore off-center to Ø8.3 mm.

| Tool | BSF special version |

| Working length | tailored to the application |

Due to the automated counterboring process, the component can now be completely processed on the machine. For this difficult-to-machine material, the customer received a solution that reliably produces a back spot face larger than double the bore diameter.