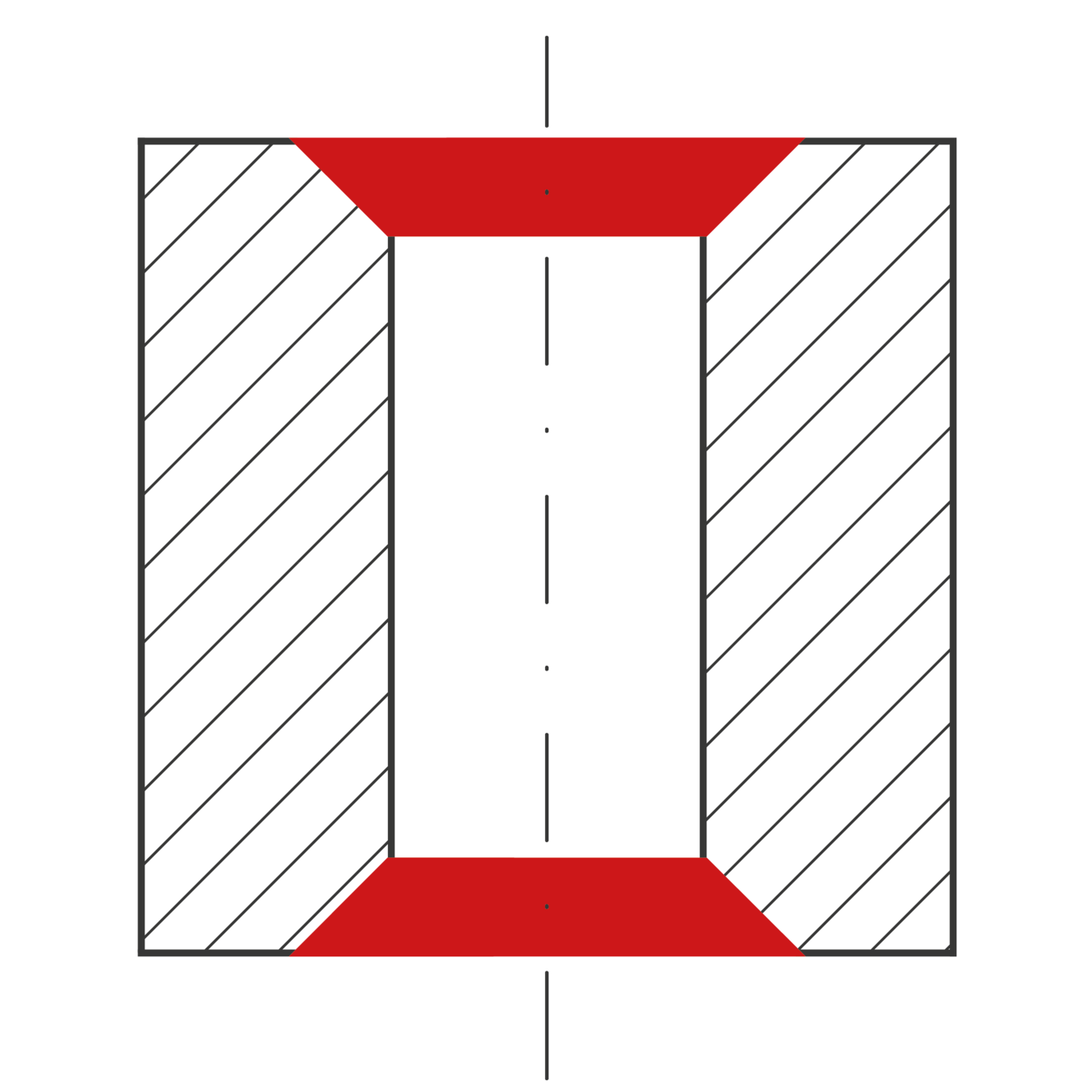

Elevator trailing wheel

Process optimisation: repeated alignment and clamping are no longer required.

A supplier to a German elevator manufacturer was looking for a solution to deburr a threaded bore on both sides without having to turn over and reposition the workpiece.

| Workpiece | Elevator trailing wheel |

| Bore diameter | Ø12.0 mm |

| Chamfer diameter | Ø14.5 mm |

| Material | GG25 |

HEULE recommended their SNAP tool with a carbide-coated blade for more demanding requirements. All machining can now be done from one side. There is no need for repeated clamping and realignment, which results in higher precision and shorter cycle times.

| Tool | SNAP5/M14 |

| Working speed | 1,100 rpm |

| Working feed | 0.15 mm/rev |

| Coolant | external coolant |

By using the SNAP threading tool, the customer saves time, money, and improves process reliability. There is no need for repeated clamping, including alignment, which results in shorter cycle times and greater precision.