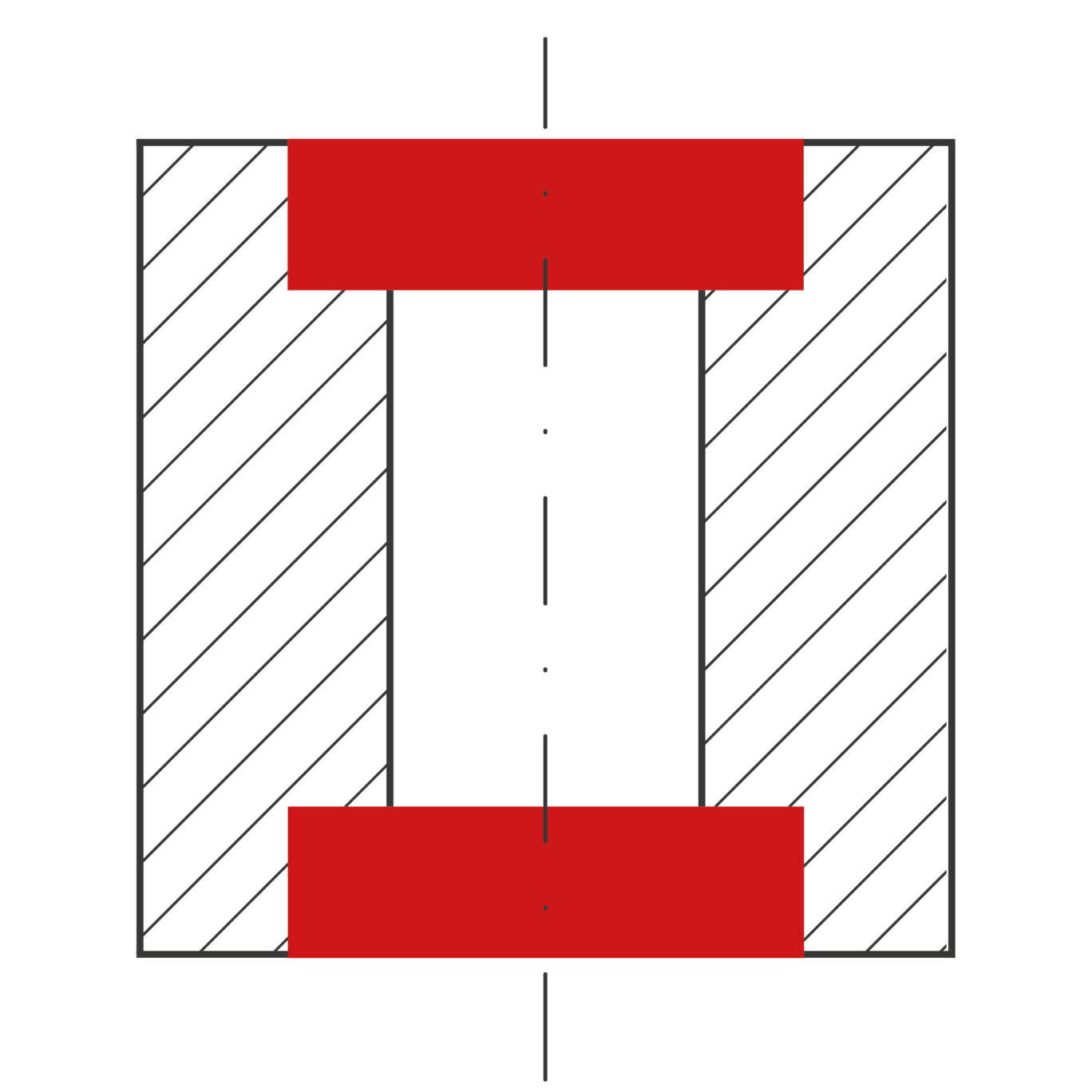

Helicopter Part

Shorter production cycles and consistent results thanks to the SOLO counterboring tool.

This customer previously used an old reverse boring bar which had to be driven into the bore off-center at spindle standstill, causing manufacturing delays. The tool also caused inconsistent results and quality problems which resulted in high quality control costs.

| Workpiece | Aviation component |

| Material | Stahl 35NCD16 |

| Parts per year | 150 |

The SOLO tool, with indexable insert, produces consistent results all within tolerance. It can be driven into the bore centric at low rpm resulting in faster production cycles.