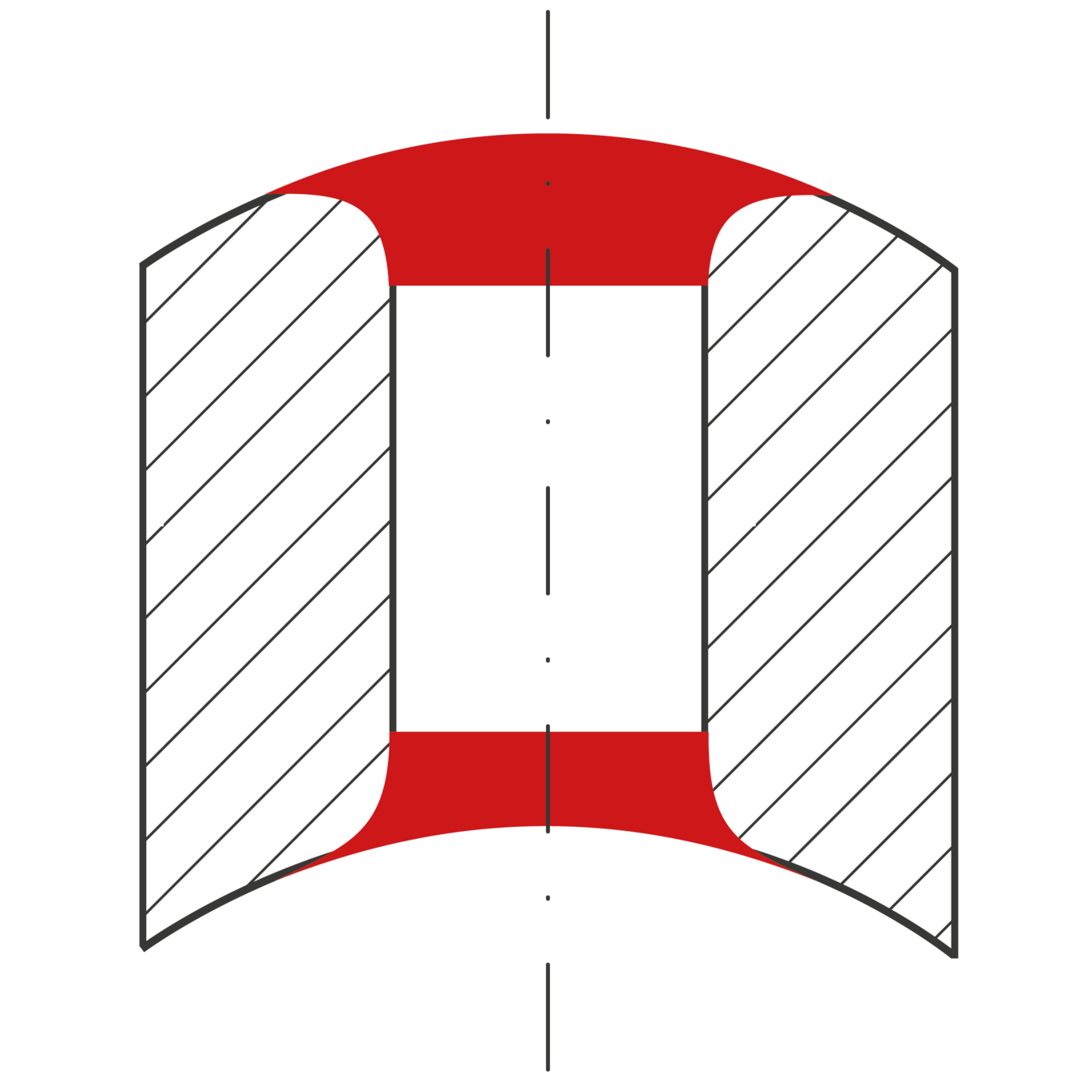

Our medical technology customer was dissatisfied with the quality and process reliability of their existing manual deburring solution for the knee system's crossbore thread run-out. Increasing numbers of bores requiring deburring exacerbated the problem. They therefore sought an automated solution.

| Workpiece | Knee Joint Replacement |

| Bore diameter | Ø6.0 mm in main bore Ø14.0 mm |

| Material | CoCrMo |

| Machine | Haas |

| Machining | horizontal |

The COFA 5M tool for bore diameter 6.0 mm was selected as a solution to this task.

| Tool | COFA5M/6.0/Z2 |

| Blade | GH-C-M0150 |

| Working speed | 500 rpm |

| Working feed | 30 mm/min. |

The complete elimination of manual processing has resulted in significant cost savings. The customer can now simply remove the fully-processed workpiece from the machine.

Machine operator's statement: «With HEULE, quality and process reliability have been vastly improved.» The decision-maker elaborates: "The specified service life of 20 workpieces per blade was clearly exceeded with more than 60 workpieces. Due to the difficult-to-machine material and the high burr formation, the tool and the solution is significantly more cost-effective than previously expected."