Steering Knuckle

Increased economy thanks to the HEULE chamfering solution.

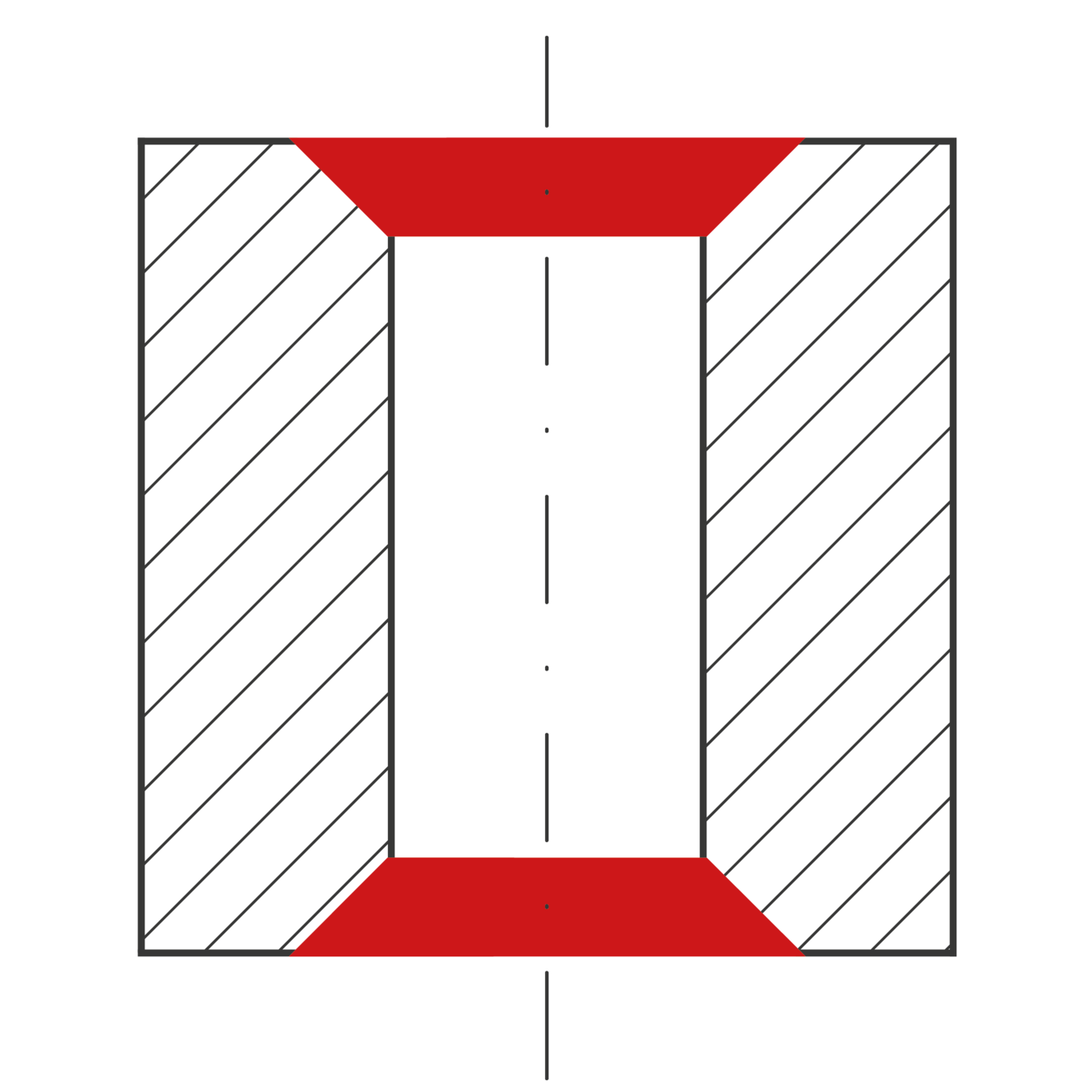

To win a large project this customer was looking for a solution to machine steering knuckles in the most cost-effective way. Relatively large chamfers had to be machined to a number of bores, forward and backwards in a single pass without having to reclamp the workpiece and without manual deburring.

| Workpiece | Steering knuckle |

| Bore diameter | several |

| Counterbore diameter | several |

| Material | cast aluminium |

The DEFA chamfering tool is chosen for these chamfering applications due to the required chamfer size, dimensional accuracy and the interrupted cut.

| Tool | DEFA |

| Working speed | 1,000 rpm |

| Working feed | 0.06 mm/rev |

| Coolant | emulsion |

The focus is on the cost-effectiveness of the solution. The cycle / production times without stopping the spindle, spindle direction change, interpolation and workpiece re-clamping was less time-consuming than alternative manufacturing processes.