Turbine Duct Fairing Re-work

Maintenance of this Turbine Duct Fairing requires the replacement of worn bolts. The countersink needed to be ro-worked.

Maintenance of this Turbine Duct Fairing requires the replacement of worn bolts. The old bolts have to be drilled out. The challenge was to rework the countersink from the same side without the need to re-clamp and align the part in the machine. Previously, this was all done manually.

| Workpiece | Aviation component |

| Material | MAR – M247 |

| Parts per year | 4'000 parts (~ 12'000 bores) |

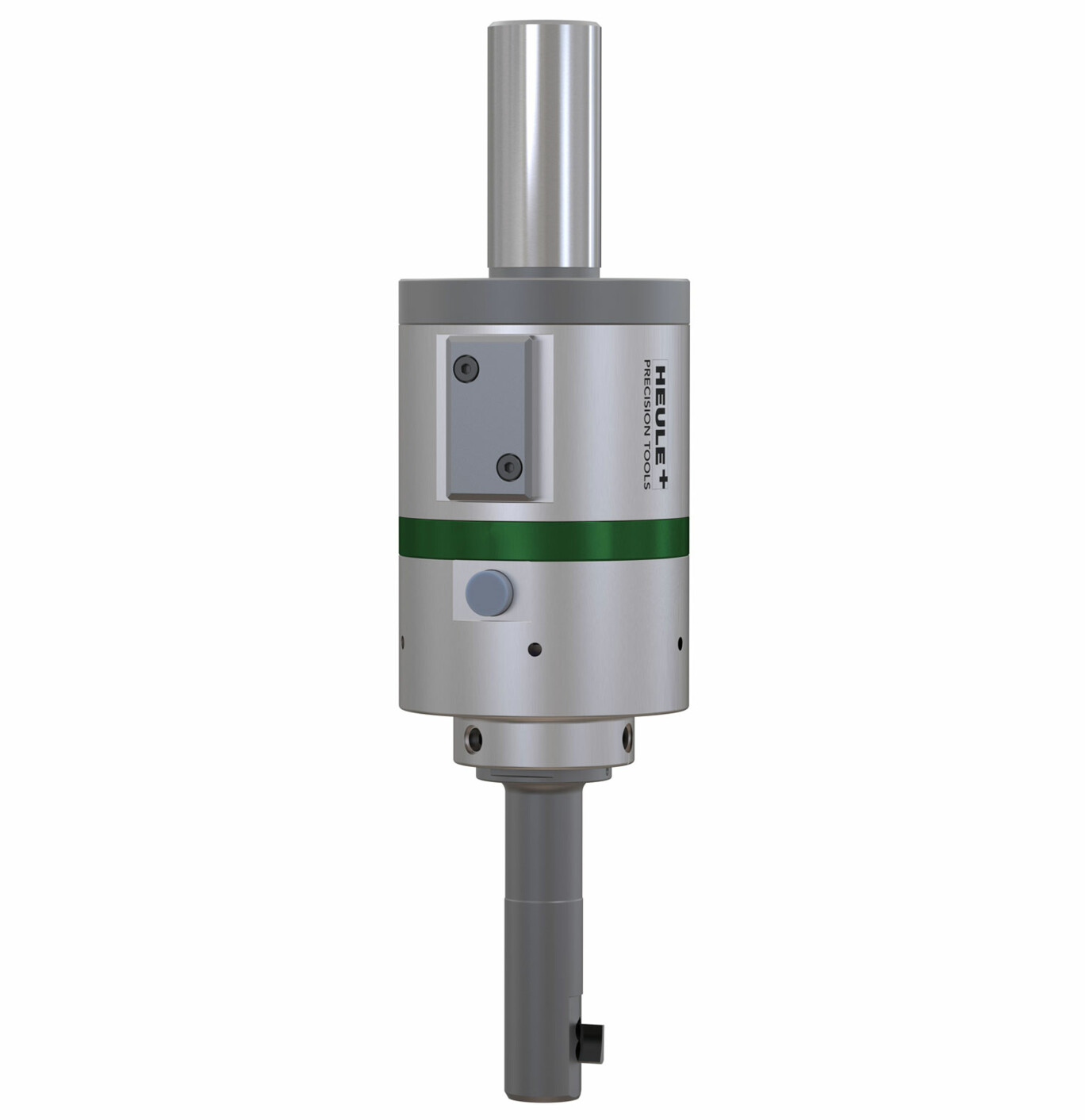

Thanks to a SOLO tool the counterbore can now be machined from the same side, eliminating the need to turn the part after drilling.