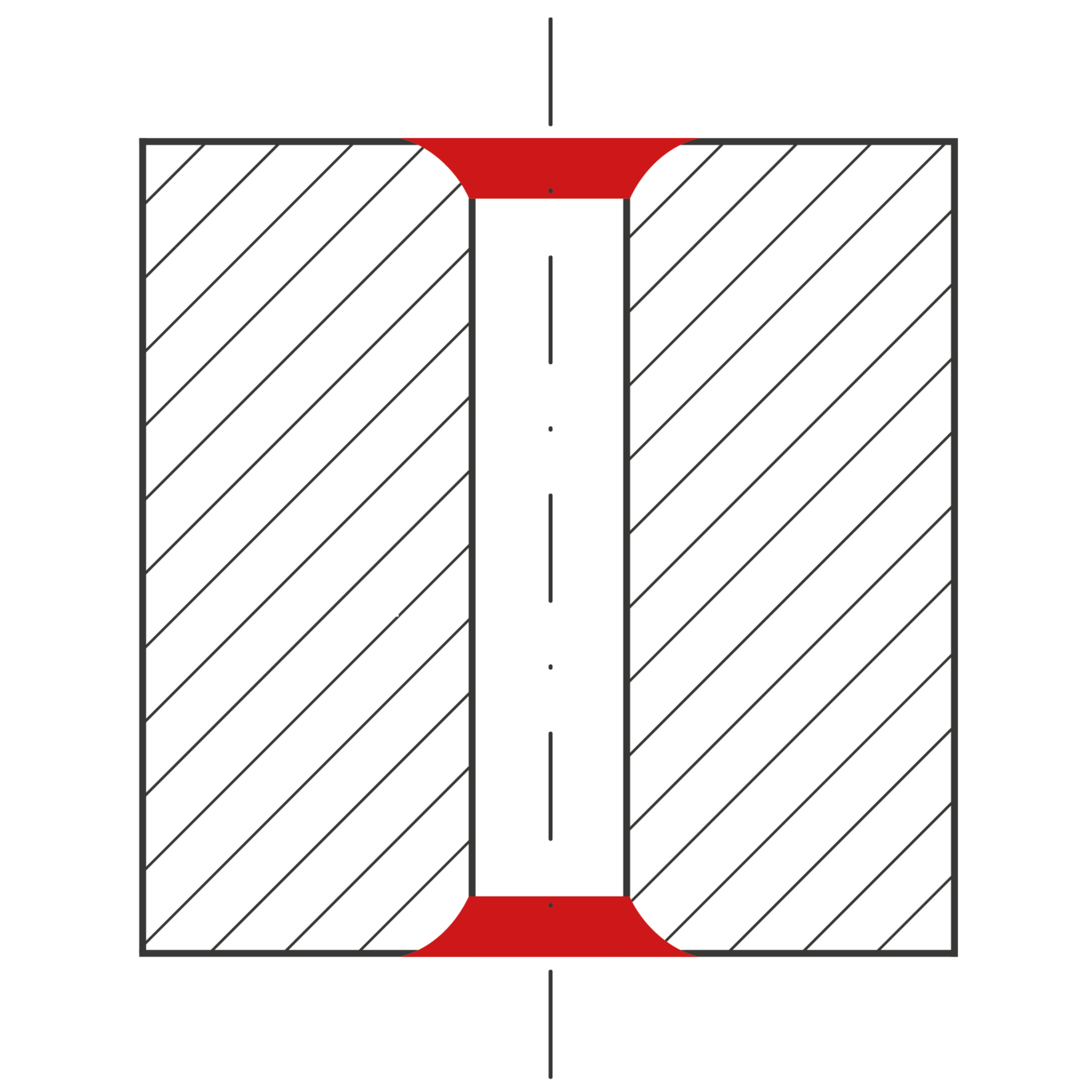

Watch case

Process-reliable series production of smallest bores

Our customer previously deburred the watch crown bore with a competitor tool but wasn’t able to achieve the required process-reliability. This resulted in excessive rework and testing costs. The main problem was that the disproportionate height of the burr.

| Workpiece | Watch case |

| Bore diameter | Ø1.5 mm |

| Chamfer diameter | Ø1.8 mm |

| Material | XcrNiMo |

| Secondary burr height | < 5 my |

The analysis performed by HEULE revealed that this production task can be accomplished by optimising the production sequence (burr reduction) and the DL2 tool. It was crucial that the DL2 uses internal coolant to reliably guide the burrs away from the cutting edge.

| Tool | DL2 |

| Cutting speed | 9,600 rpm |

| Working feed | 0.007 mm/rev |

The solution co-created with the customer ensured the reliability of series production.