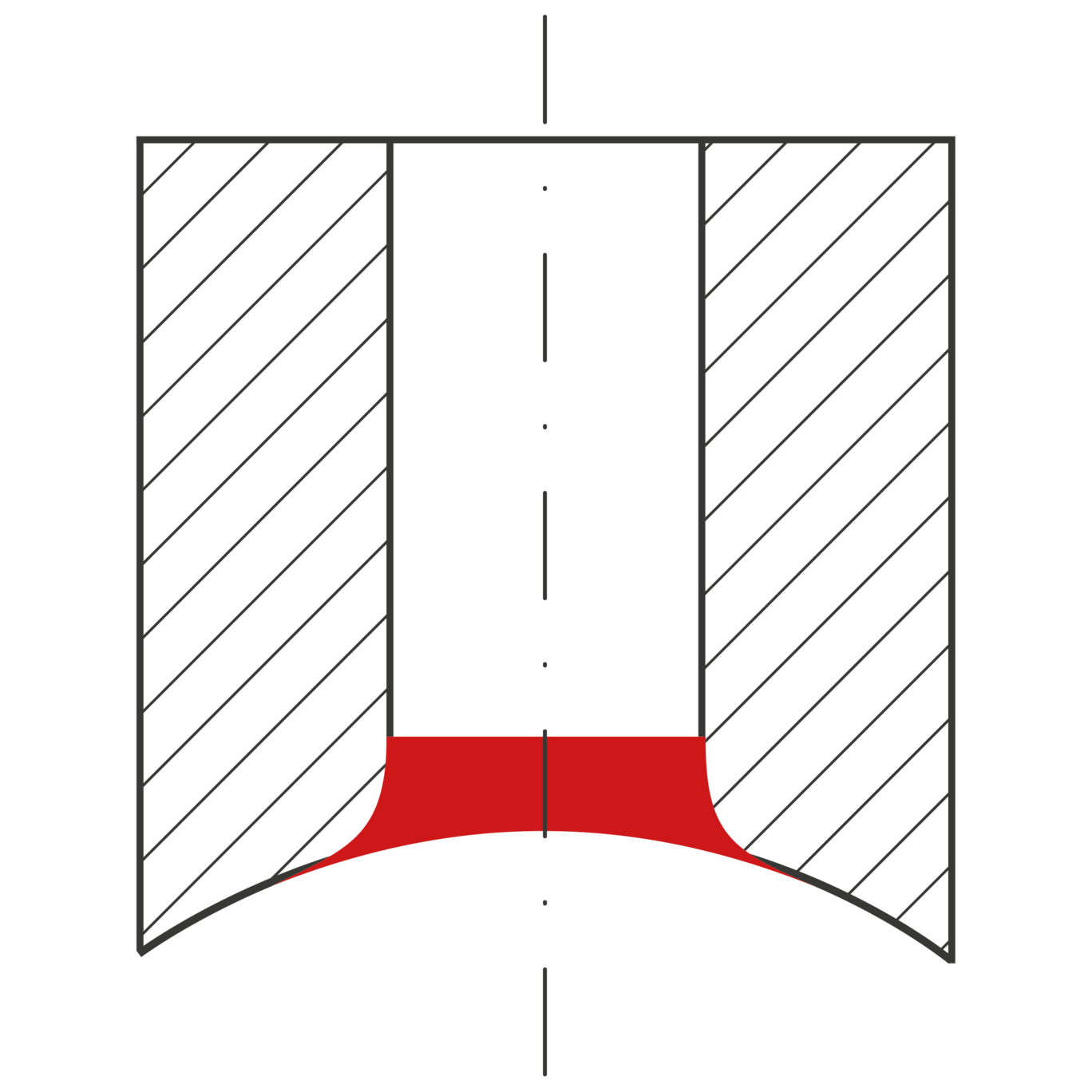

Our German customer produces over 1 million Common Rails annually. He was looking for a solution to automate the reverse deburring of the low pressure bore. Previously, our customer deburred common rails with a competitor tool. Blade life was not satisfactory and deburring quality was not reliable, resulting in frequent and expensive quality assurance problems.

| Workpiece | Common Rail |

| Low pressure bore | 2.4 mm |

| Main bore | 9.0 mm |

| max. Deburring diameter | 2.8 mm |

| Material | forged case-hardened steel (1,000-1,300 N/mm²) |

The solution proposed by HEULE is the simple and economical SNAP tool. The edges of the bore are deburred and chamfered without rotating the workpiece or stopping the spindle.

| Tool | SNAP 2/2.4 |

| working length | 30 mm |

| blade | SNAP blade 2.8 mm diameter made of carbide with a TiAlN coating |

| Working speed | 3,300 rpm |

| Cutting speed | vc 25 m/min |

| Working feed | 0.05 mm/rev |

The customer is completely satisfied with the high level of process reliability and the deburring quality. Previously, the common rails were deburred with a competitor tool. The blades designed specifically for tough materials have a service life of 2'000 bores. Thanks to the SNAP tool's reliable deburring, the process costs have been reduced.