Railway line

The HEULE solution automates the chamfering of both sides of the bores for stable and reliable process. Due to mechanical deburring, it is no longer necessary to purchase new machines.

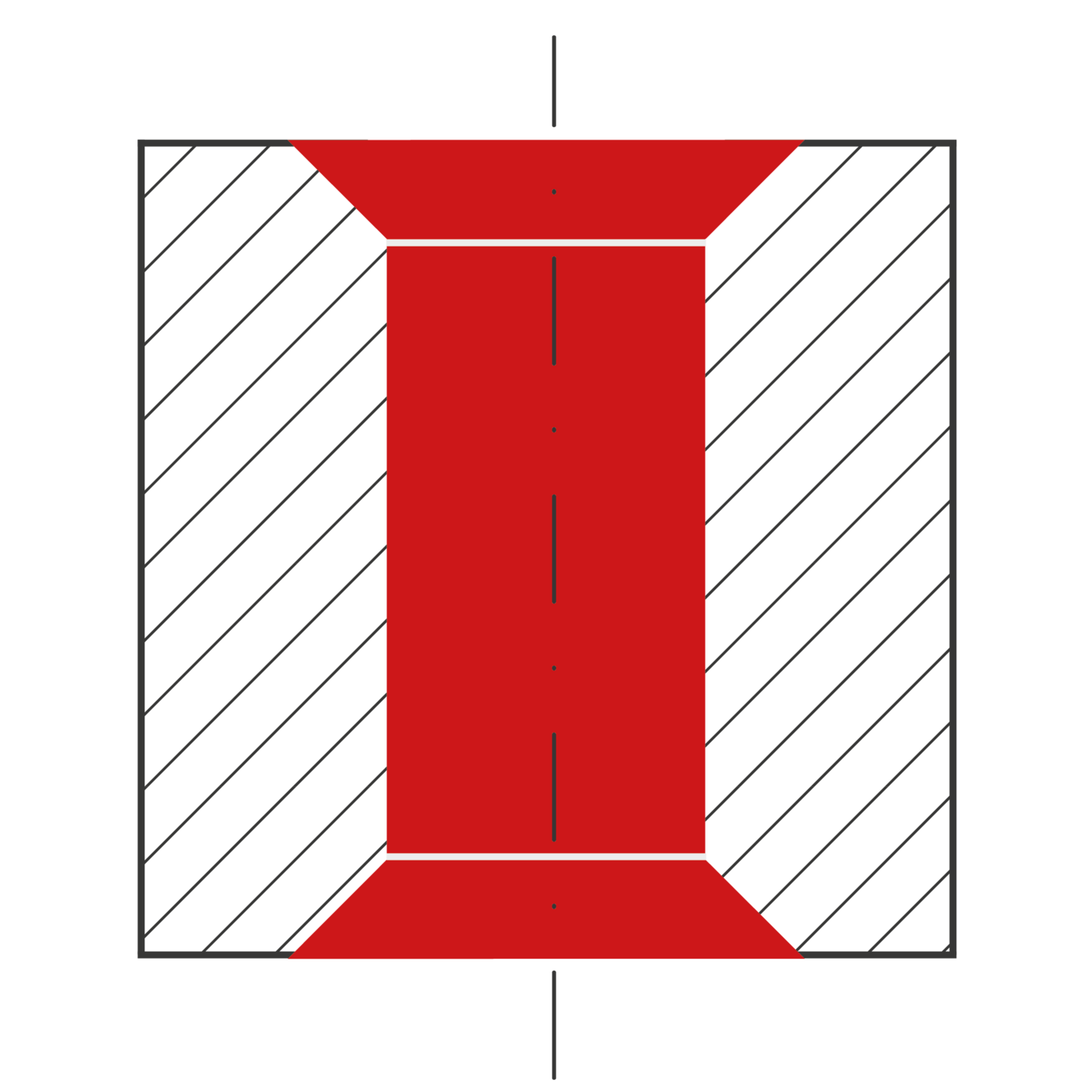

A customer from India required a solution for drilling bores to connect 260 metres of rails. For reasons of safety, they were required to modify the rail. The front and back chamfers were being applied manually, which has not proven to be an ideal method.

| Workpiece | Rail |

| Bore Ø | 32.0 mm +/- 0.2 mm |

| Chamfer Ø | 34.0 mm +/- 0.1 mm |

| Material | Steel |

| Machine | Special drilling machine |

| Machining | Horizontal machining with internal coolant |

| Volume | 1,500,000 pieces/year with 2 bores each |

A customised combination tool is used for this application.

| Tool | SNAP CombiGH-QO-2687 |

| Working speed | 510 rpm |

| Working feed | 62 mm/min |

| Coolant | internal coolant |

The HEULE tool and the machine processing it enables eliminate the costs associated with manual setup. The solution enables chamfering with the existing machines and equipment. This prevented huge investment in new equipment.