The production of bores and counterbores in aluminium wheels requires the use of four different tools today. The process plan also requires turning the workpiece. The repair work and corresponding downtime to adjust the repaired tools are considerable. The high cost of the existing tools and the absence of a reliability guarantee for the process were sufficient reasons to reconsider the current production sequence.

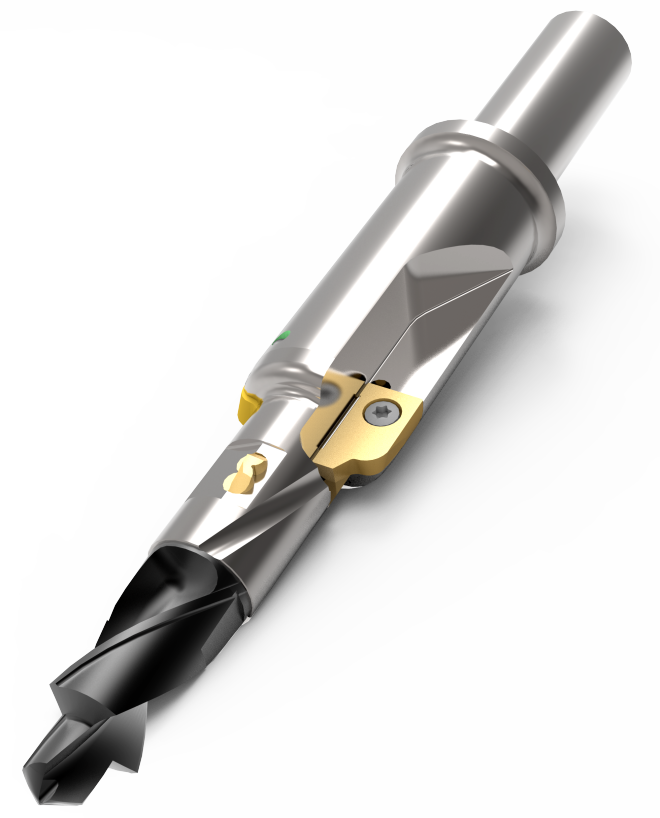

HEULE’s custom VEX-S tool combined four existing tools into on resulting in massively reduced machining times, eliminated manual deburring and increased process reliability.

| Tool | Drilling-Countersinkcombination tool |

| Tool body | VEX-SNAP5 special version |

| Blade | SNAP5 Ø11.6 DLC / GH-QM-15547 backward cutting only |

| WSP | 30° plate carbide coated |

| Drilling cutting data | Working speed: S = 2,750 rpm Working feed: F = 550 mm/min |

| Chamfer cutting data | Working speed: S = 2,750 rpm Working feed: F = 450 mm/min |

The customer is extremely satisfied with the result and the time savings achieved. The working feed and working speed for countersinking and chamfering must be adjusted appropriately for applications involving multiple processes performed with a single tool. Internal coolant is required to flush the chips away. HEULE chooses the most stable tool design possible to eliminate vibrations. The available space serves as a guideline for dimensioning the special combination tool. HEULE special tools are renowned for their ease of use and process reliability.