A Korean manufacturer of hydraulic components and bolt connections / fittings was looking for a safer and more efficient solution for deburring the crossbore of a ball valve. The aim was to automate the process. Until then, employees were laboriously removing the burrs from the bore edges by hand with a brush.

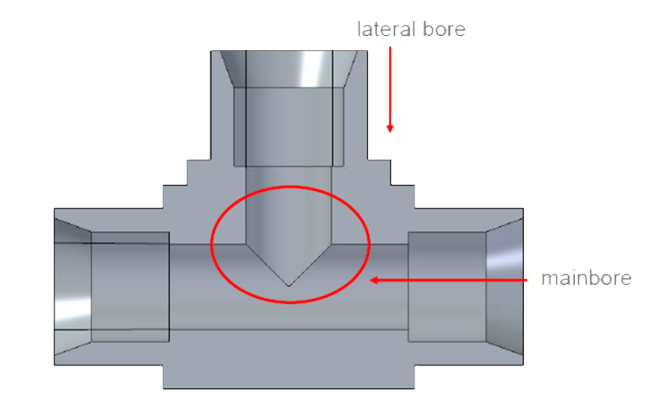

| Workpiece | Fitting / Hydraulic T-Piece |

| Cross bore | Ø10.4 mm |

| Main bore | Ø10.4 mm |

| Material | SS316 |

| Machine | DOOSAN CNC machine |

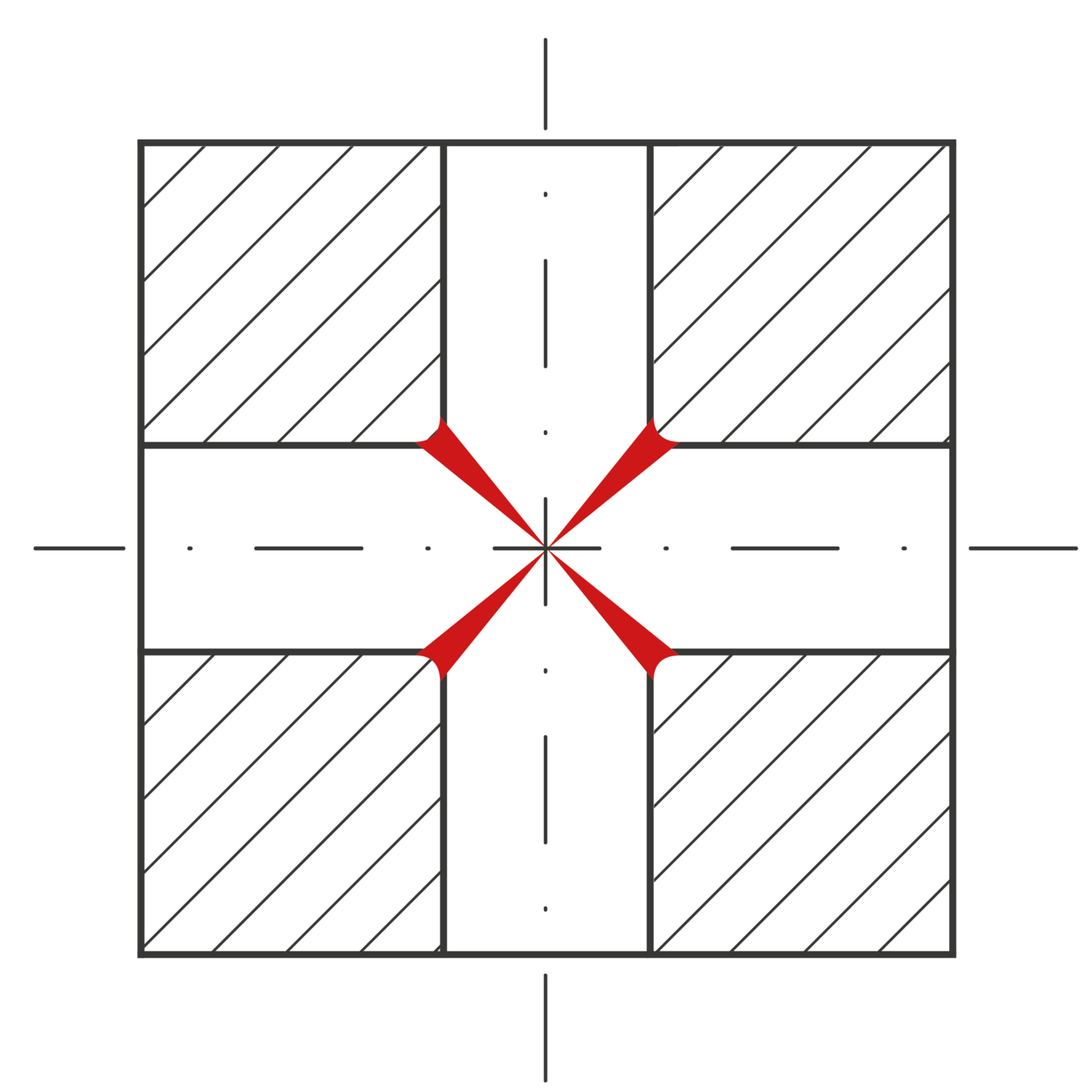

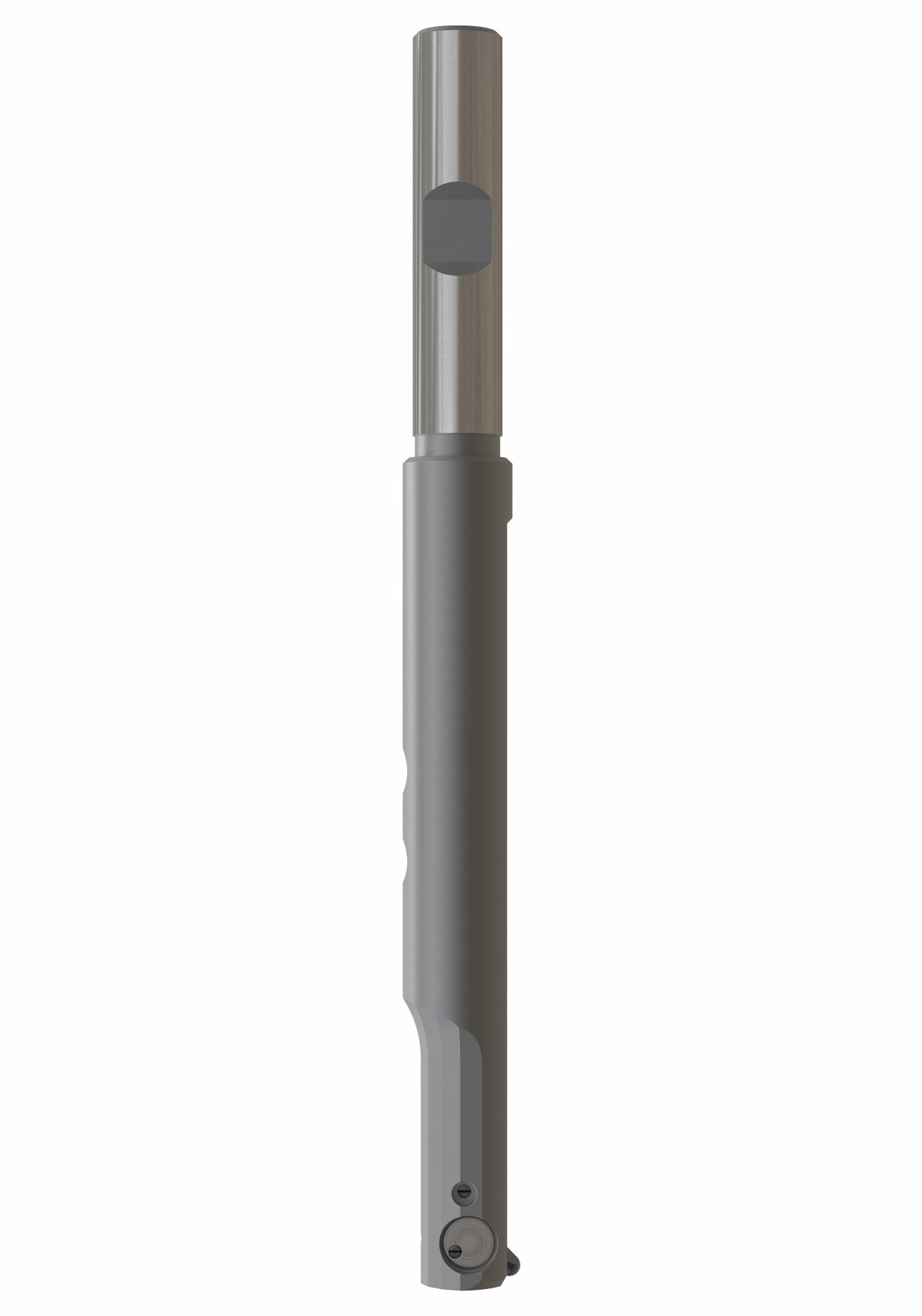

The deburring of crossbores with a 1:1 bore diameter ratio posed a unique challenge for HEULE. The tool solutions that were available so far could not cope with the extreme unevenness of a 1:1 bore. HEULE had to find a completely new approach to the solution. They found it by using both new machine capabilities and by developing a special version of the COFA tool (COFA-X). The combination led to success.

| Tool | COFA-X |

| Speed | 500 RPM |

| Working feed | 0.06 mm/rev |

| Coolant | external coolant |

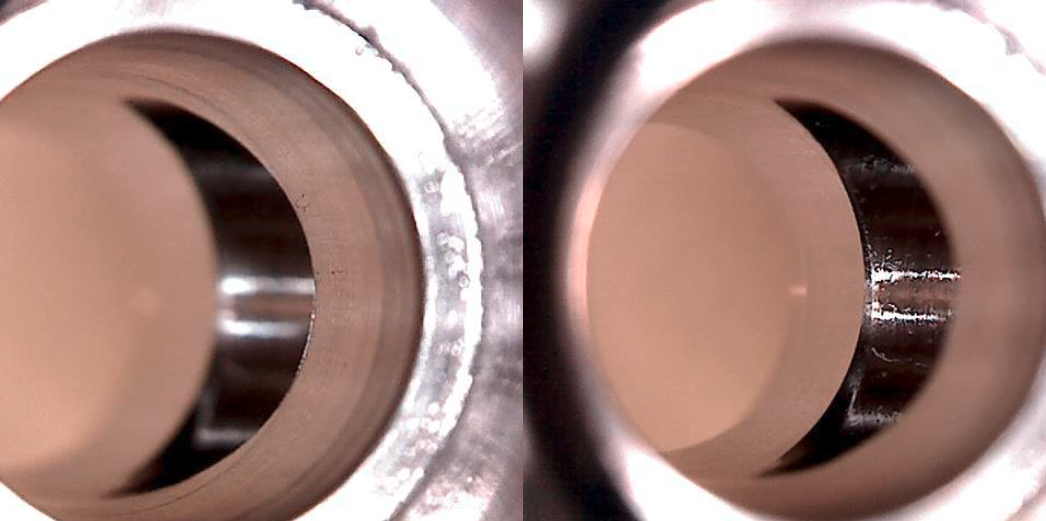

The possibility of automating the deburring process and the significantly increased process reliability have resulted in substantial cost savings for the customer. Similar T-Pieces are now being made as a result of the successful pilot project.

The images show the bore after COFA-X processing.