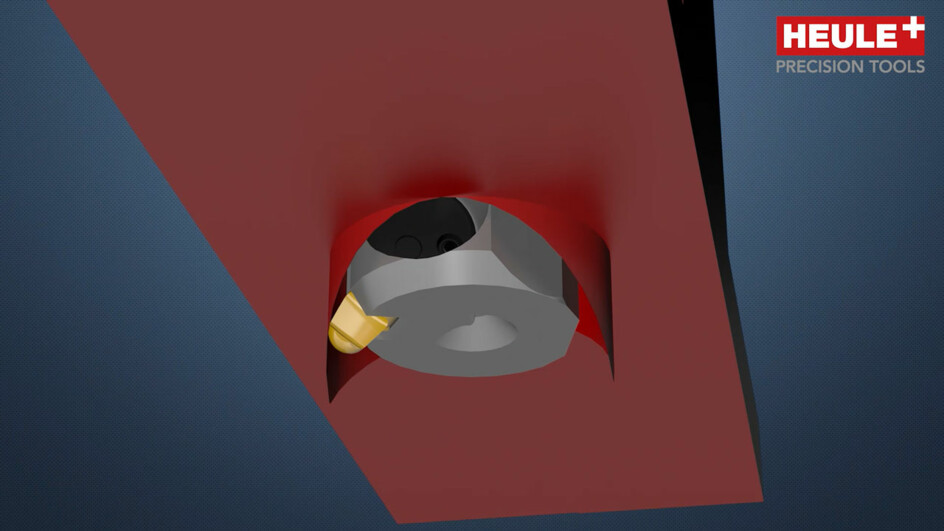

COFA-X

Mechanical deburring of crossbores up to a bore ratio of 1:1

- Individual adaptation to the application

- Solutions starting from bore diameter of 5.0 mm

- Completely chamfered edge – the edge is burr-free

- Optimised for CNC machining operations

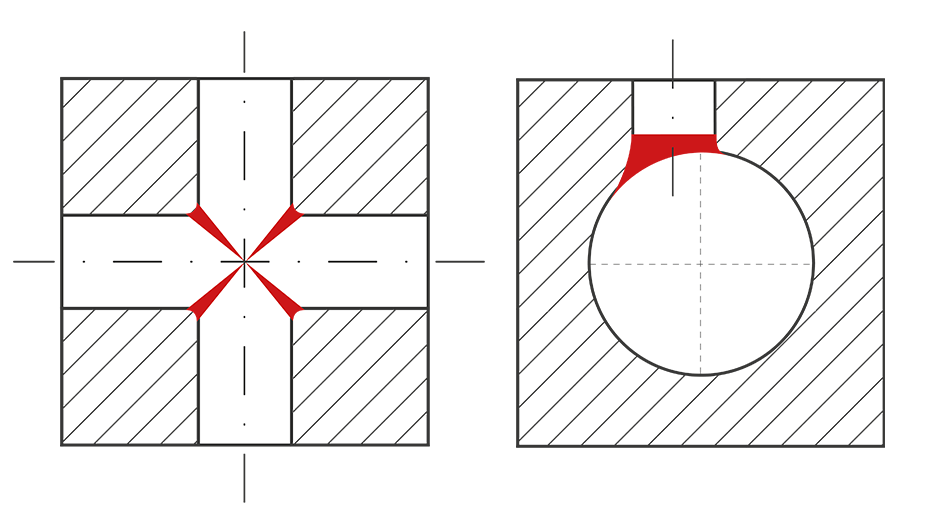

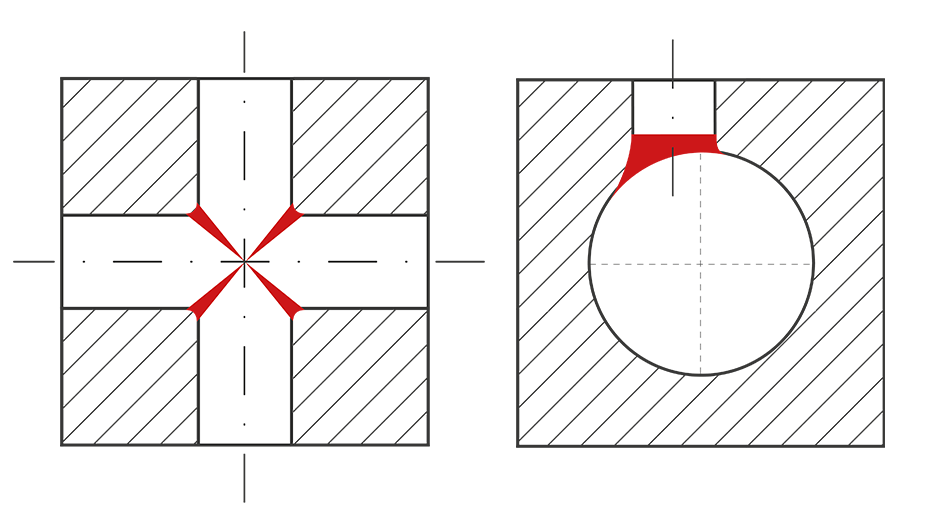

Mechanical deburring of crossbores up to a bore ratio of 1:1

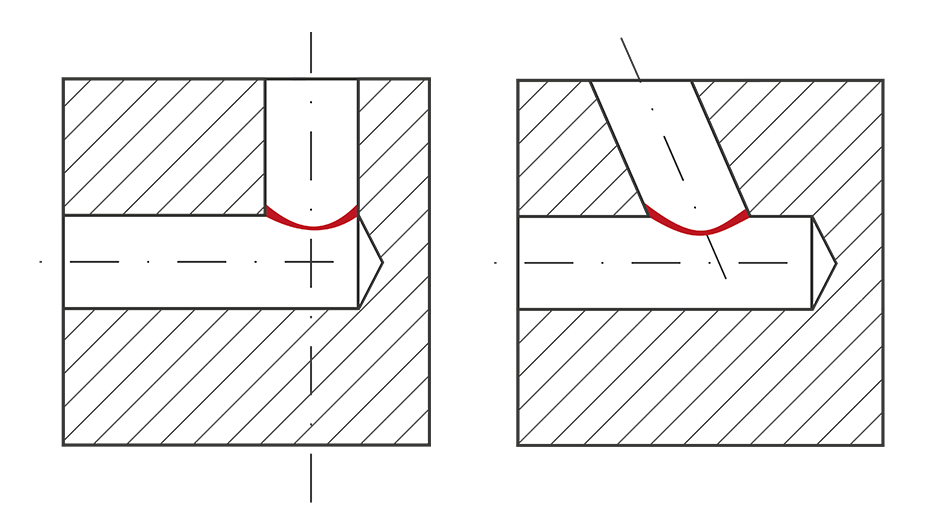

Each COFA-X tool is designed for the individual application. It is a solution for deburring the edges created by intersecting bores (crossbores) having a main bore to cross bore ratio of 1:1. It can also be used for intersecting bores with offset axes. The COFA-X starts from a bore diameter of 5.0 mm.

For each application, we require a precise application description in order to provide the correct solution. Please define the parameters and characteristics of the application as precisely as possible.

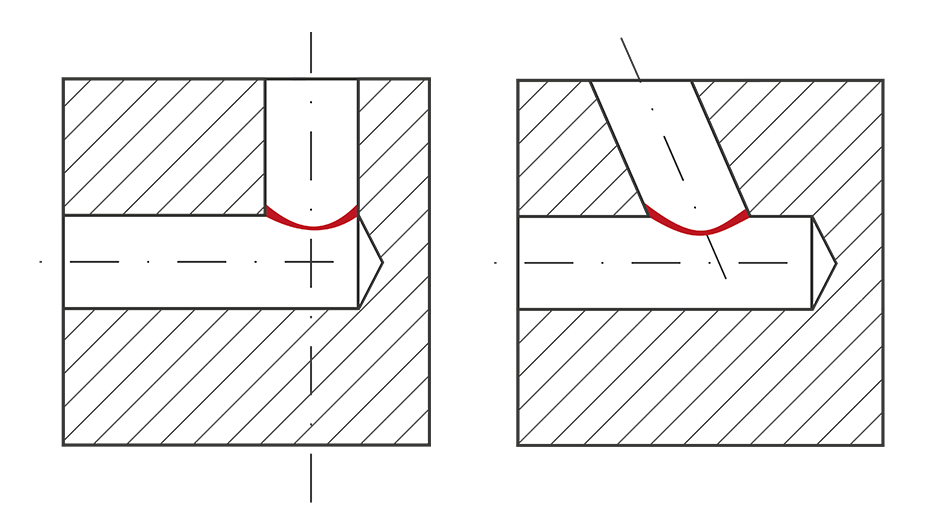

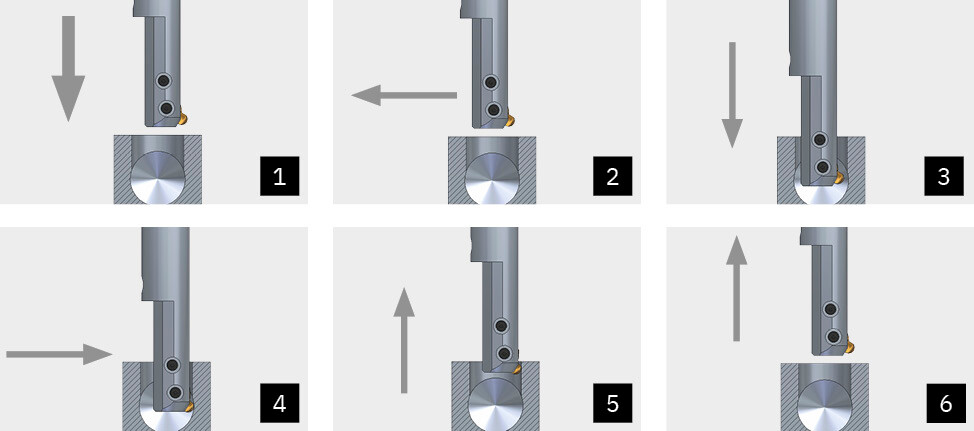

The tool concept is simple and is based on the COFA system. However, the blade is pre-tensioned so that it can follow the large bore unevenness. The tool body is also optional. This release is required for the COFA-X to move off-centre into the bore, as the blade cannot fold in due to the pretension in one direction.

The coated carbide blades are designed either exclusively for forward machining or exclusively for machining the back of the workpiece.

Two screws secure the replaceable spring to the tool body. After processing, this spring returns the blade to its starting position.

The COFA-X removes burrs from the very uneven edges caused by intersecting internal bores. This mechanical deburring solution for crossbores can be used in CNC operations and significantly improves process reliability.

In use, for example when deburring the back bore edge, the deburring tool is moved off-centre (with spindle stopped) to the bore centre axis to allow entry of the tool into the bore. It is moved back to offset value 0 for deburring. The deburring process then occurs in reverse working feed. The edges of the bore are machined without producing secondary burrs. At the end of the crossbore deburring process, the blade retracts into the tool body and the tool rapidly traverses out of the bore. This is done without having to stop the spindle.

Would you like additional information regarding the X-BORES family and COFA-X technology? Click through our downloads.

Find out how in our 20-minute Online Seminar "Deburring CROSSBORES". Just click on the link and take a look.

Thanks to our worldwide network of branch offices and approximately 50 sales partners in 35 countries, HEULE competence and know-how is always within quick and easy reach.