Our customer is a major supplier of different components to the recreational vehicle (RV) industry in the US. They contacted us after researching machine deburring options.

They required assistance with several applications for deburring crossbores on one of their high-volume manifolds, which is manufactured in multiple configurations. In the past, the manifold hole burrs were removed using thermal/explosive deburring as a secondary off-machine process.

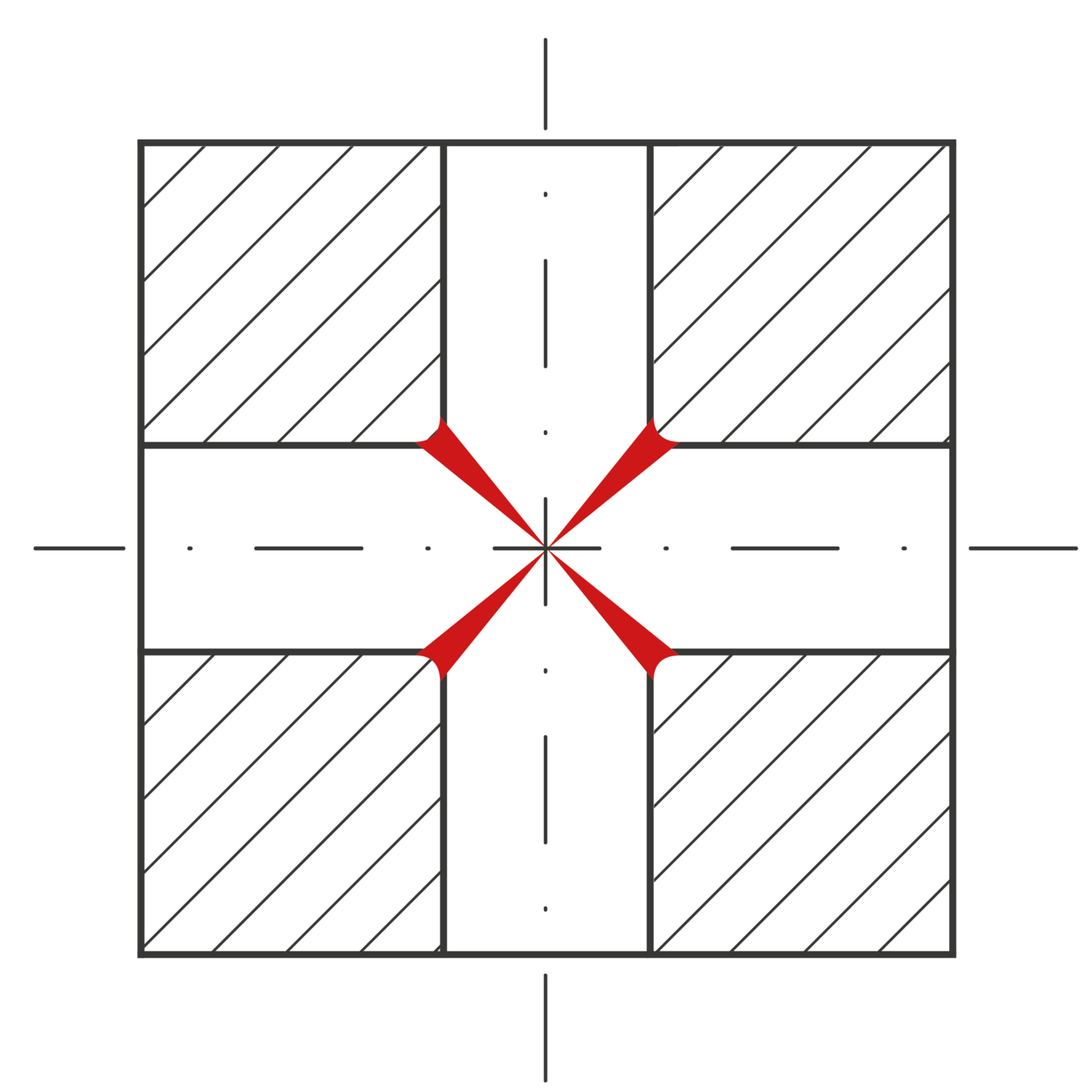

The .391-inch Ø bore through the SAE #4 port that intersected the two VC08-2 cavity ports, proved to be the main challenge. These intersections create a 1:1 crossbore ratio.

| Workpiece | Manifold |

| Bore diameter | Ø0.391" / Ø9.93 mm |

| Material | Aluminium |

| Machine | HAAS Super VF-2 |

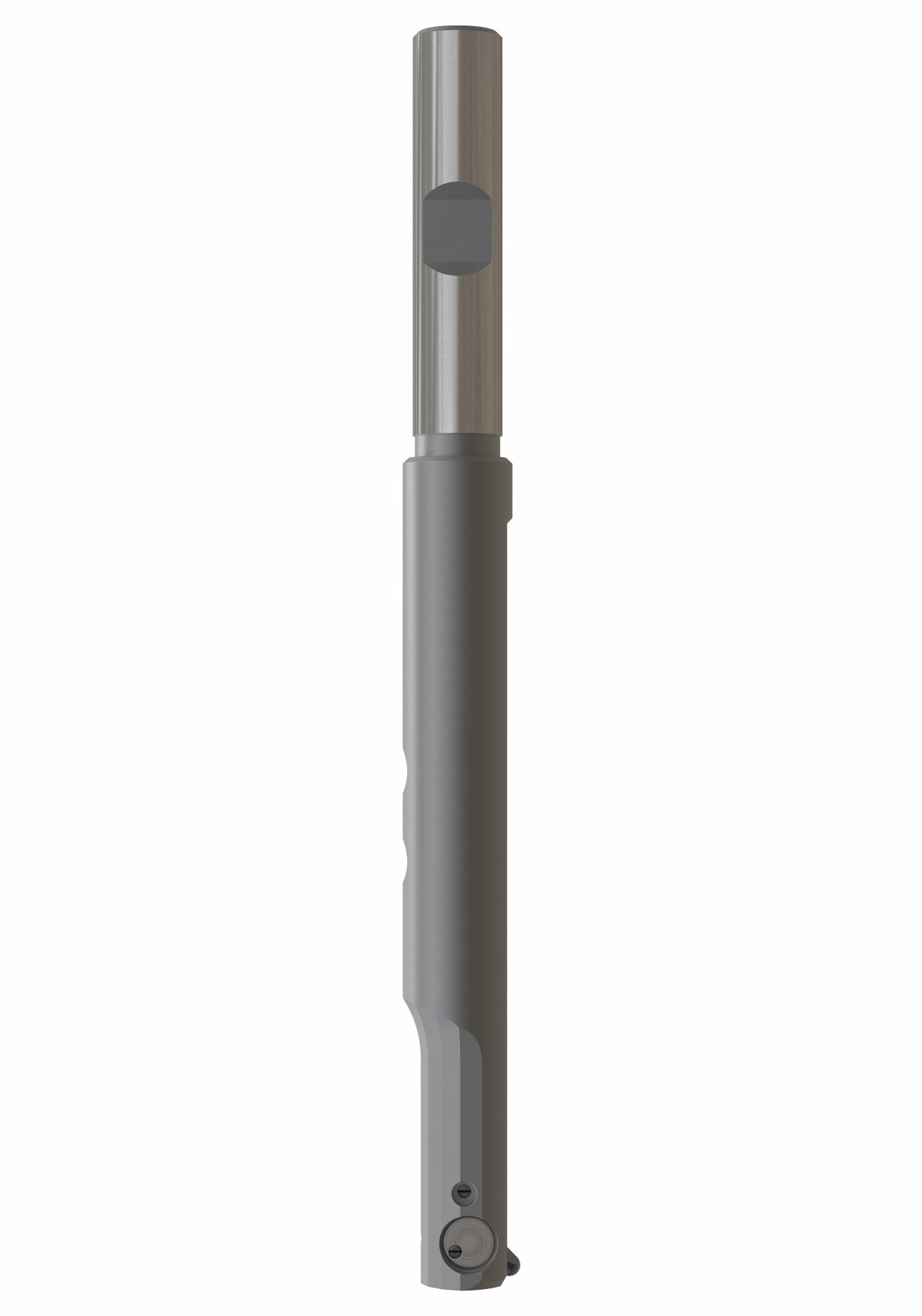

After an initial review, it was determined to use a standard SNAP tool for the Ø.281" mounting bores and a standard COFA tool for the .250" through bore in the SAE #4 port.

The analysis by the HEULE technicians revealed that deburring these intersects would be possible with one COFA-X tool that only cuts from the front and another that only cuts from the back. The customer was presented with this solution. They agreed and requested assistance to conduct the initial tests in HEULE's own test workshop. For this purpose, they provided non-deburred parts for process development.

The customer has replaced an expensive external secondary machining process (thermal deburring). They anticipate fine-tuning the program as needed and installing additional standard tools for this part process in order for the machine to produce a fully finished part. The initial manual deburring and secondary processing have been eliminated.

The customer reports that the tools perform precisely as desired. From verifying the initial test results to on-site testing at their factory, they appreciate that HEULE has helped them accurately test the process for which they were seeking a solution.