Deburring refers to the process of removing burrs that remain on the edges and bores of workpieces after machining (milling, turning, drilling). Burrs are undesirable material residues that affect the safety, functionality, and aesthetics of the workpiece.

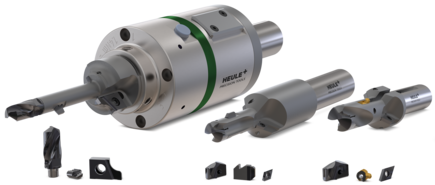

Mechanical Deburring Tools from HEULE

HEULE offers a wide range of mechanical deburring tools specifically suited for deburring metal parts. The tools enable final machining of the workpiece directly on the machine. Back-bore machining eliminates further process steps, optimising costs and process times. The automated processes are also characterised by high repeatability.

Deburring

Uniform deburring on both sides in a single operation – without turning the workpiece.

Chamfering

Economical chamfering of bores, front and back, in a single operation.

Combined Drilling

Economical drilling combined with deburring, chamfering, or counterboring.

1

2

3

4