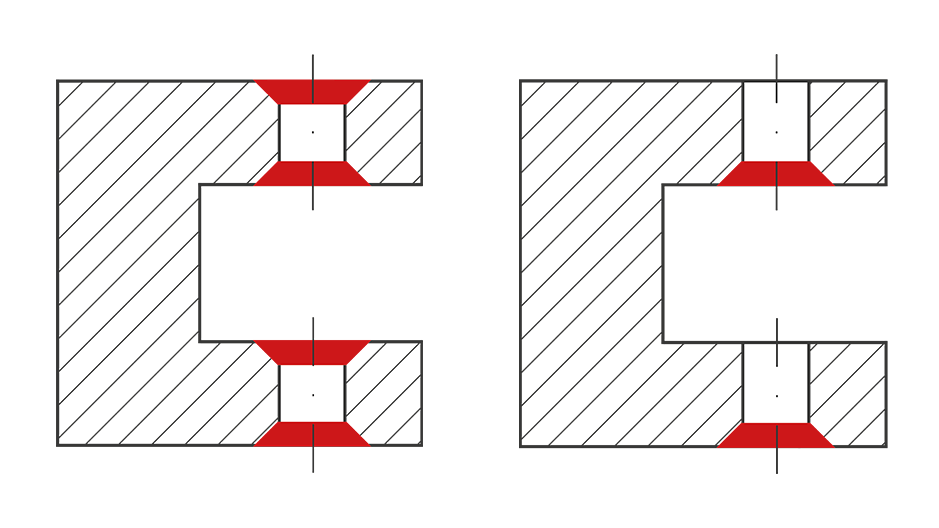

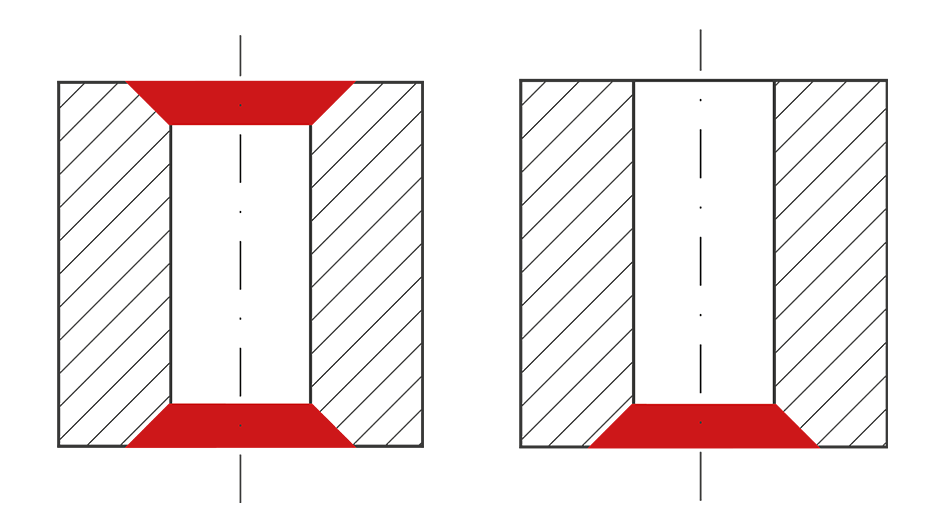

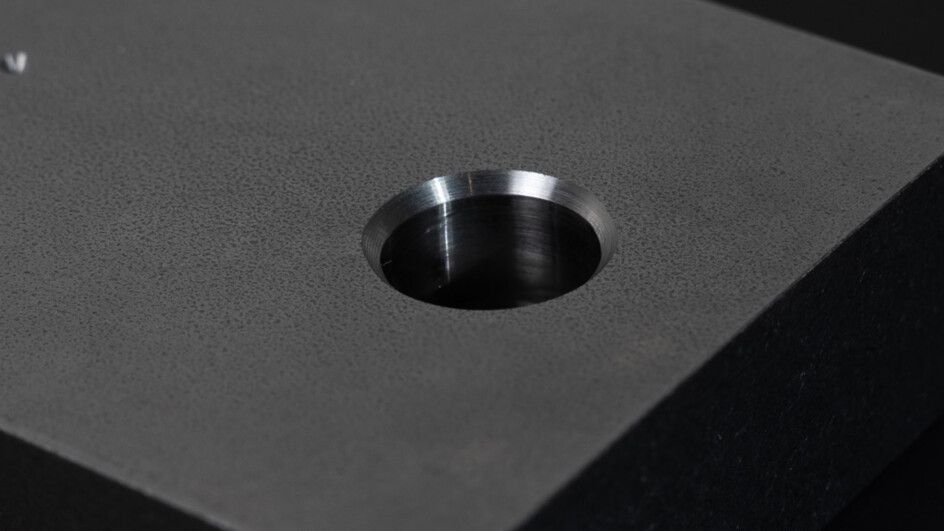

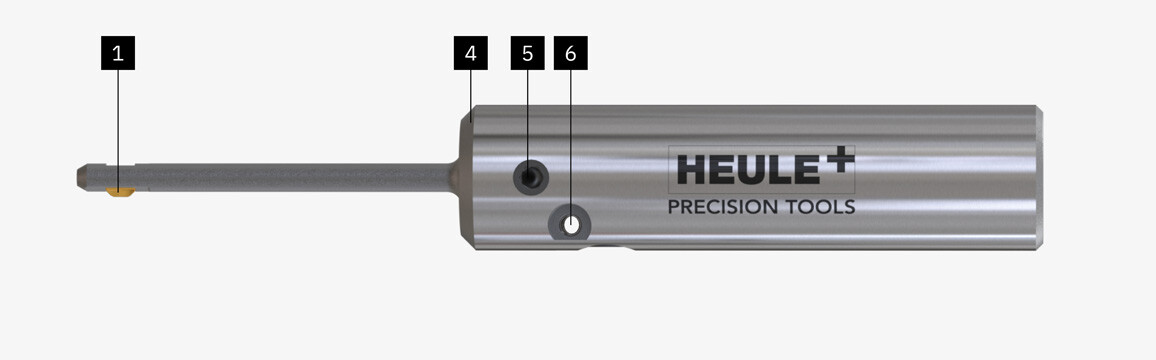

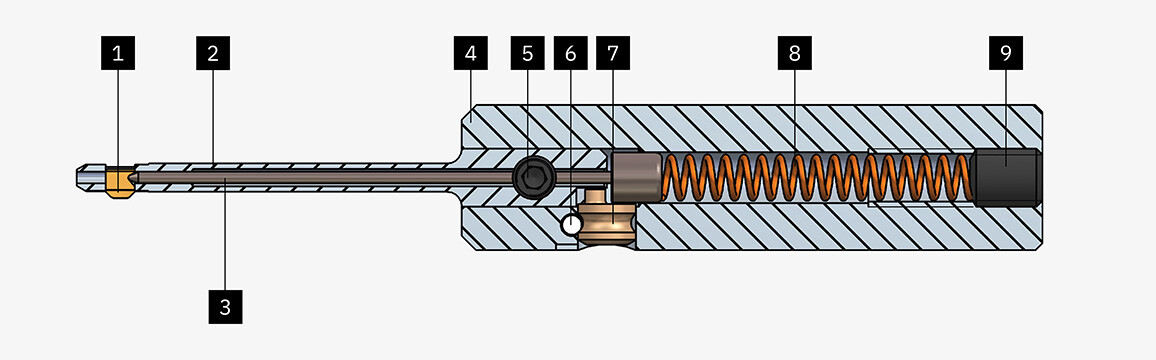

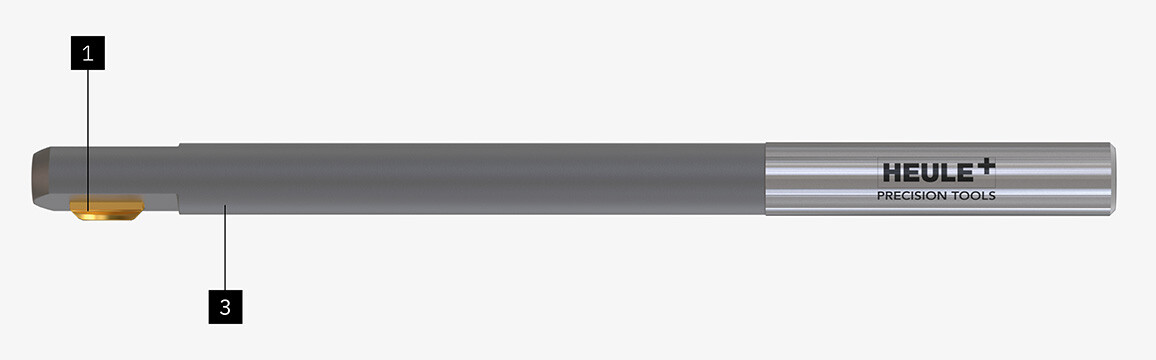

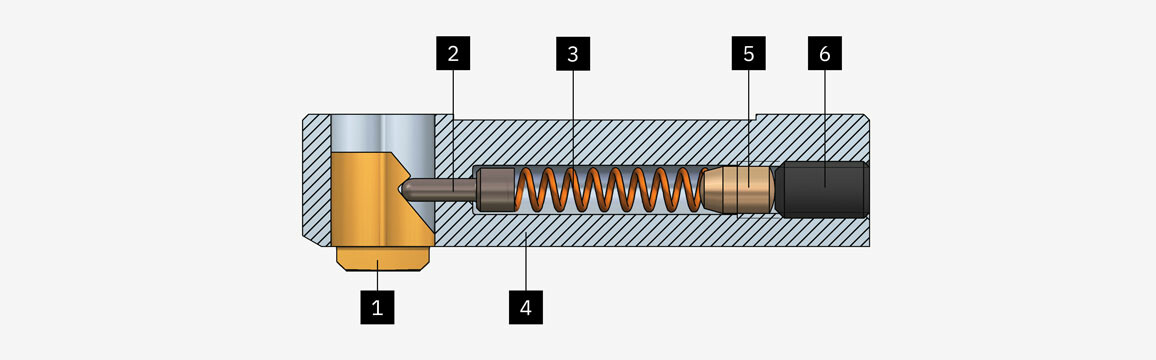

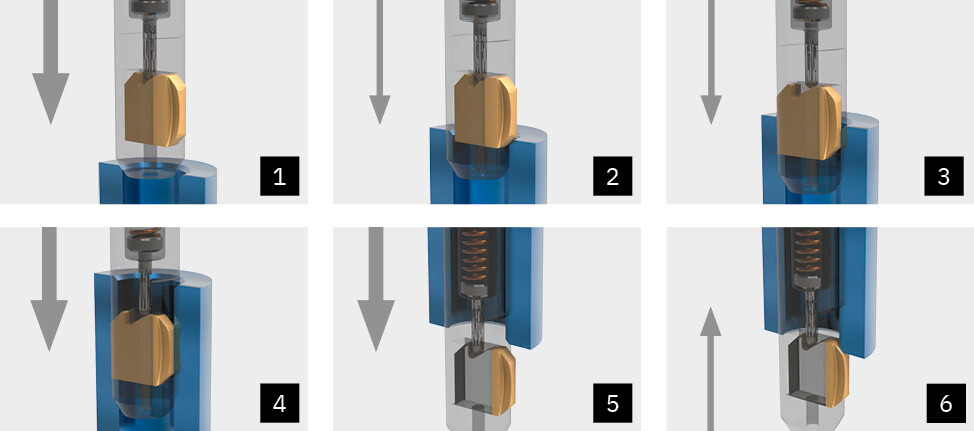

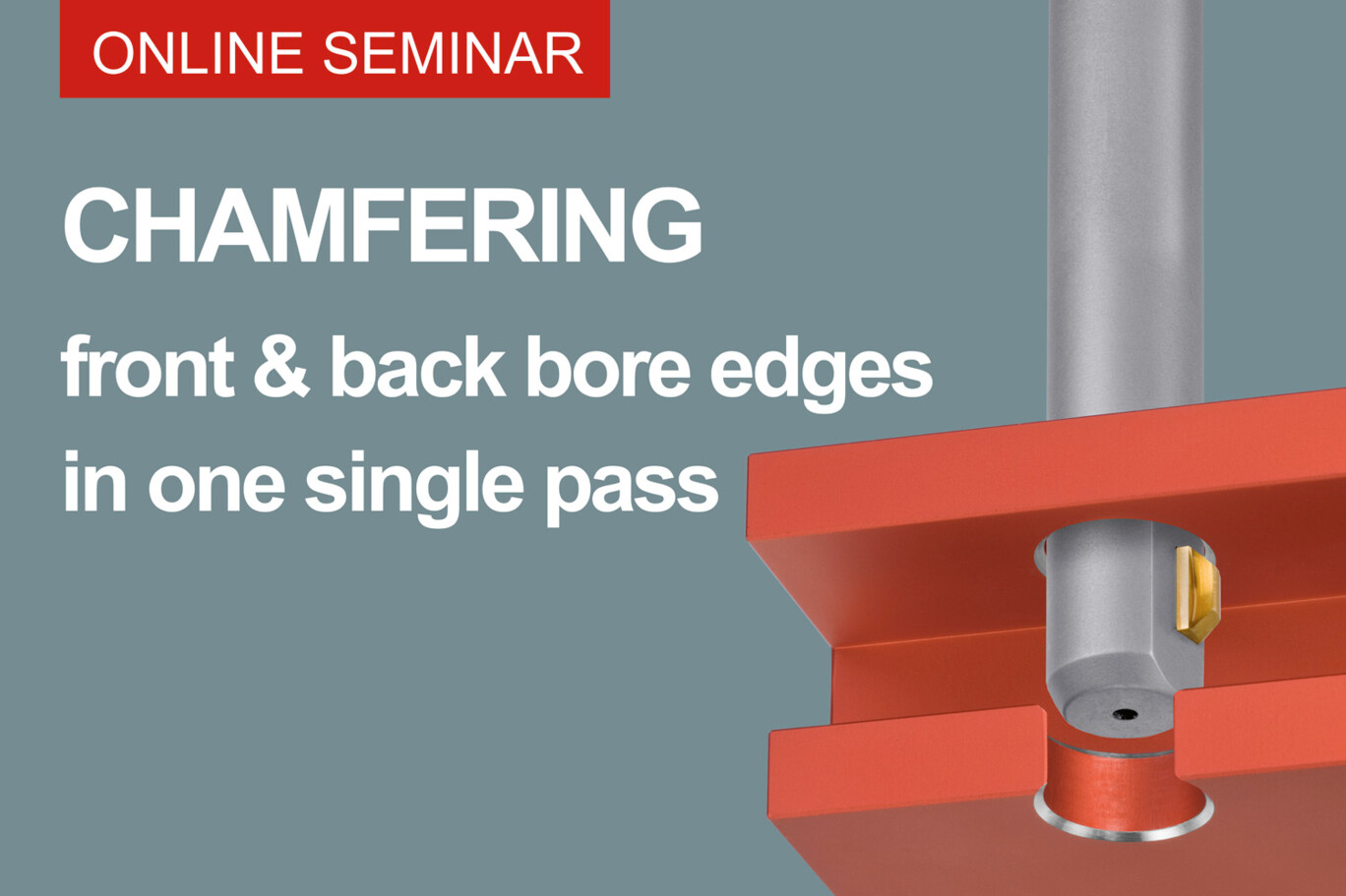

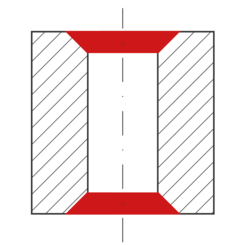

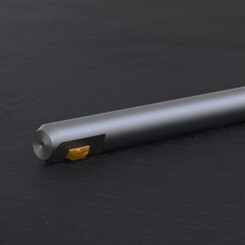

The desired chamfer is created on the front edge of the bore in working feed and working speed. Upon reaching the chamfering depth, which is defined by the blade geometry, the blade retracts radially into the tool body. Next, the tool will rapidly traverse through the bore without stopping the spindle. A specially designed sliding section on the blade prevents damage to the surface of the bore – even with reamed bores.

When exiting the bore, the spring-loaded blade returns to its neutral position. The rear edge of the bore is now chamfered in backward working feed. Once the chamfer has been cut and the blade has fully retracted into the tool body, the chamfering tool can be removed from the bore in rapid feed. The result is clean and uniform chamfer front and back, in a single pass.

The chamfer size is always constant, even if the position of the edge changes due to tolerances (e.g. cast parts).