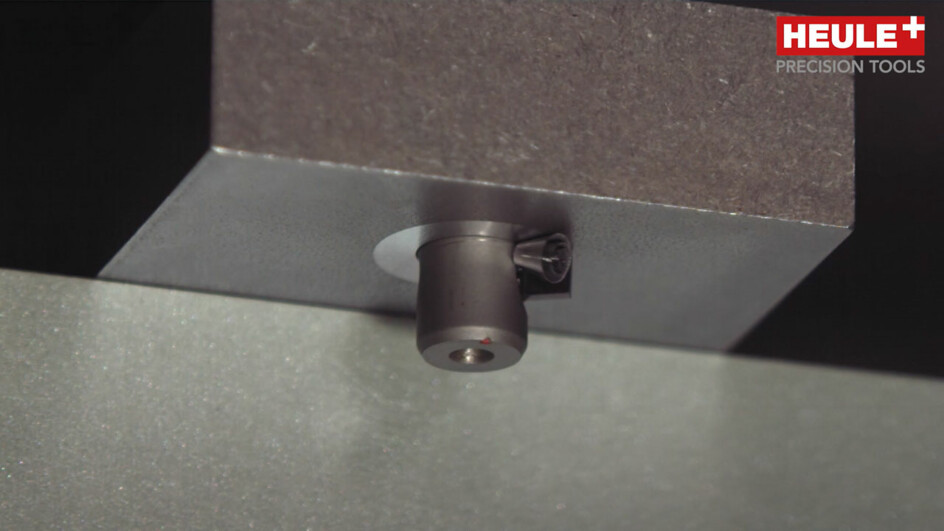

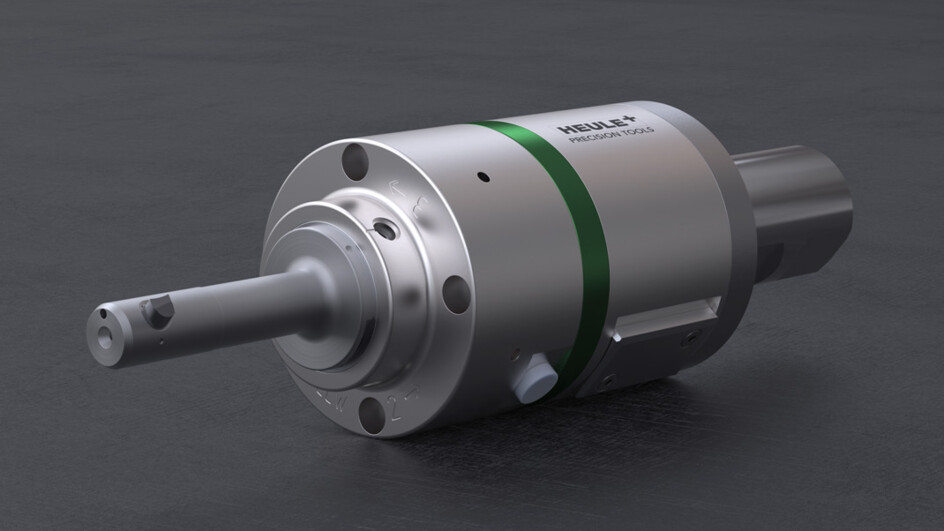

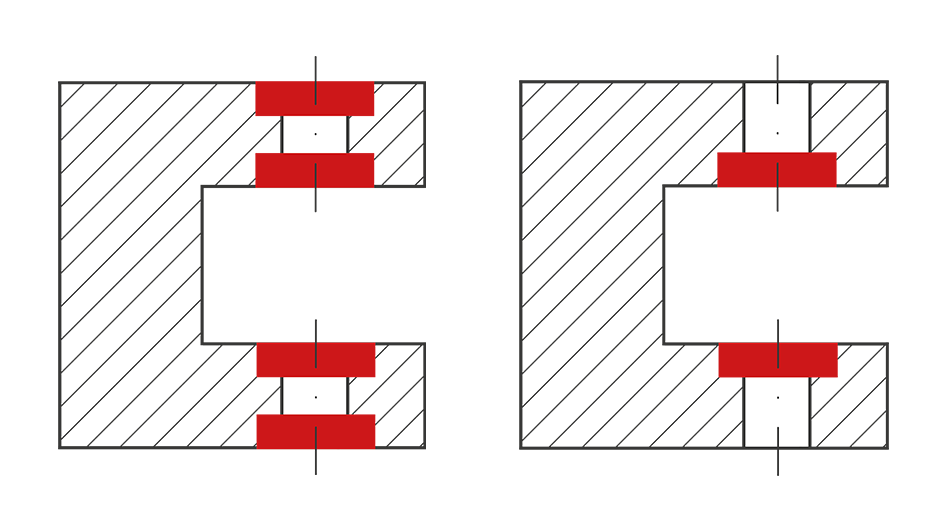

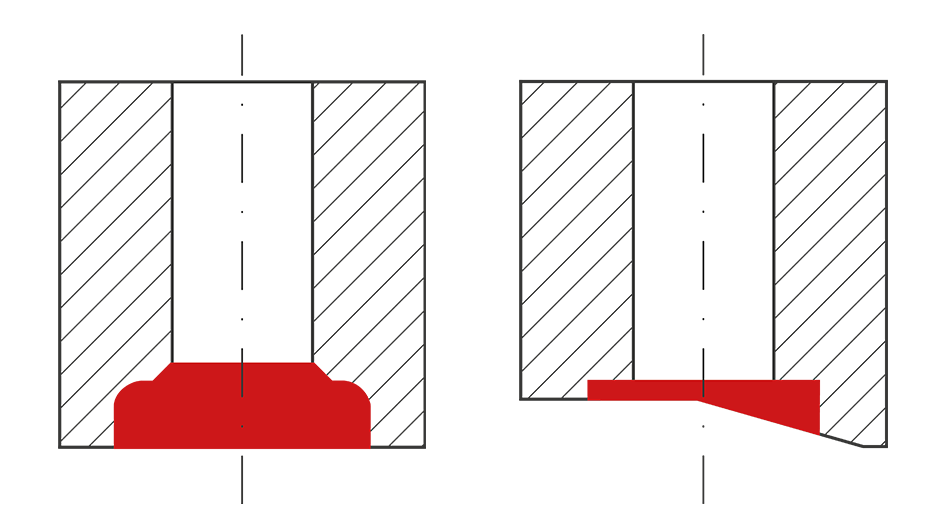

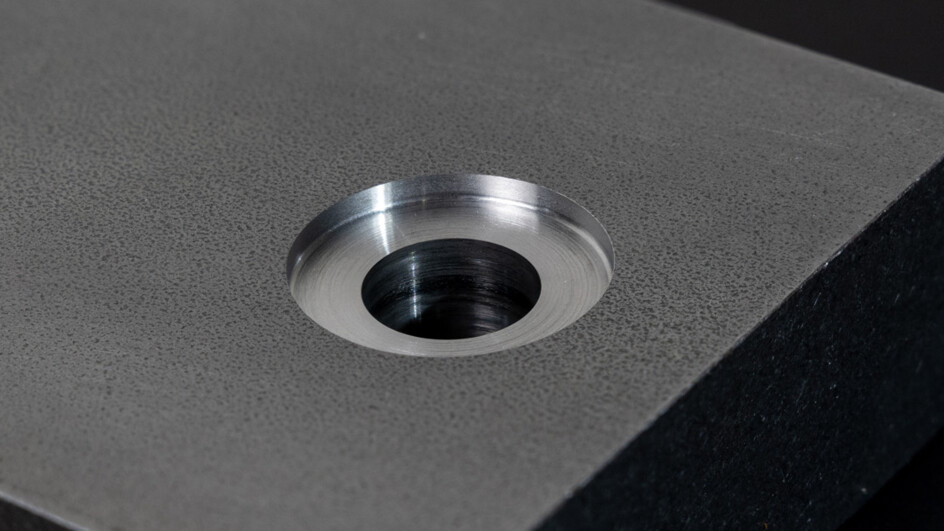

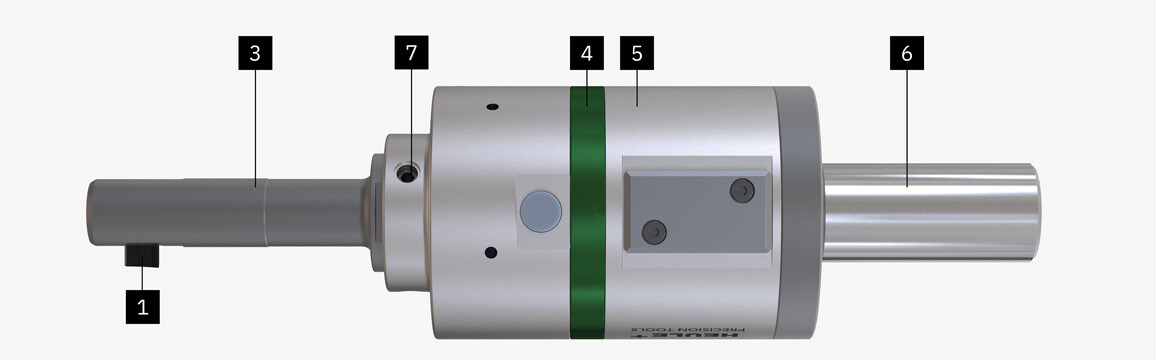

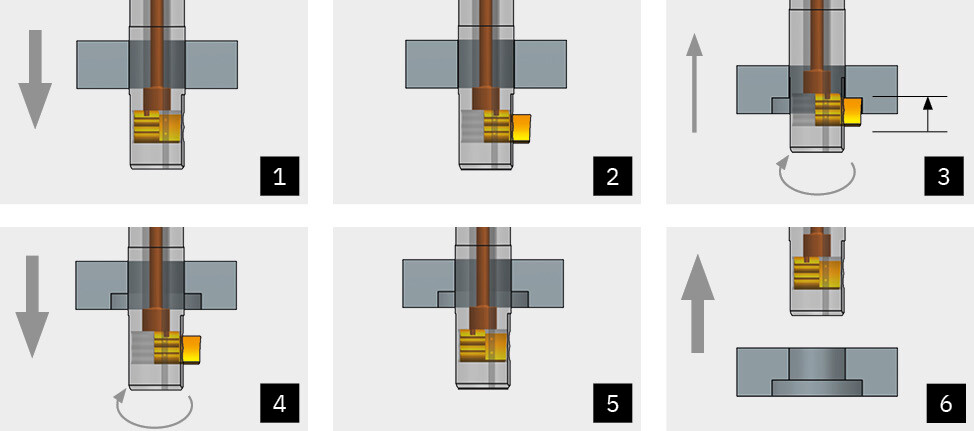

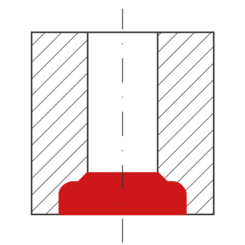

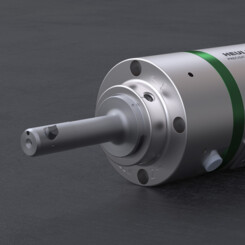

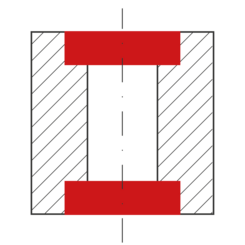

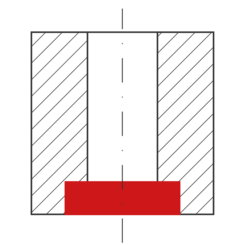

With SOLO and SOLO2, HEULE offers extremely robust counterboring tool systems. The combination of a mechanical process steps description and simple construction guarantees maximum process reliability and minimal maintenance. Externally, the two systems are nearly identical. However, the mechanical setup is different.

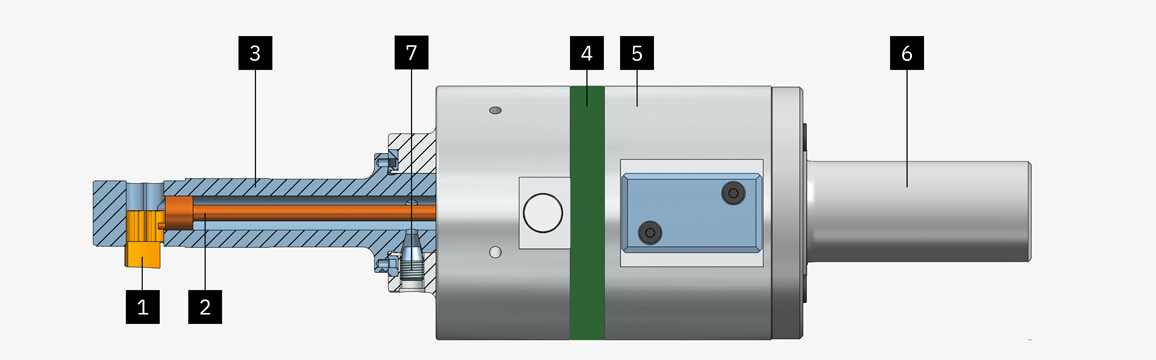

The control unit and shank are standard on both variants. Blade housing, blade control and blade are custom-designed to meet customer requirements. The control unit contains two centrifugal weights and is sealed against dirt and coolant. The manually replaceable carbide blade’s cutting geometry and coating are material-specific.