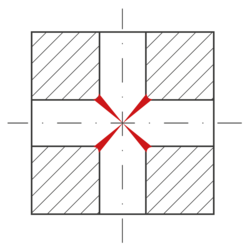

Crossbores 1:1 / COFA-X

The mechanical deburring tool for crossbores up to a bore ratio of 1:1.

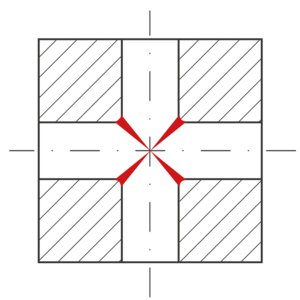

Intersection / SNAP-X

Deburring of several crossbores that all penetrate into a main bore. This is a custom development.

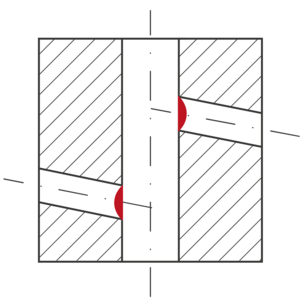

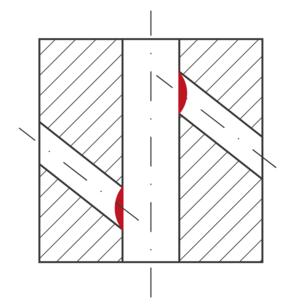

Oil bores / CBD

Deburring of classic oil bores as well as very complex bore intersections. This is a custom development.

Solutions for your specific application

Your application is not shown? We would be pleased to offer advice and develop a solution tailored to your specific requirements.

1

2

3

4