CNC deburring is an automated process by which burrs are removed from metal workpieces. Special mechanical deburring tools are used, which are integrated into CNC machines. The biggest advantage: The workpieces come completely finished from the CNC machine.

Selecting the Right Deburring Tools

The choice of deburring tool is crucial for the quality of the final product. Decisive aspects include material type, workpiece geometry, integrability into the process, and the requirements for the result.

HEULE, as an experienced manufacturer of mechanical deburring tools, offers a wide range of solutions. This includes a proven standard range as well as solutions individually adapted to the application.

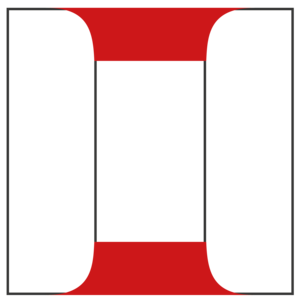

Deburring

Uniform deburring on both sides in a single pass – without turning the workpiece.

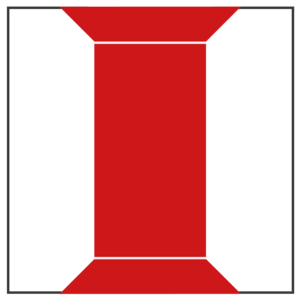

Drilling Combined

Economical drilling combined with deburring, chamfering, or counterboring.

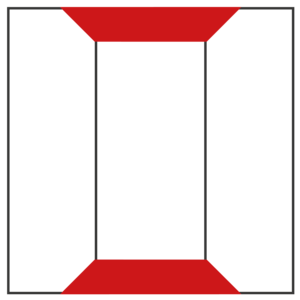

1

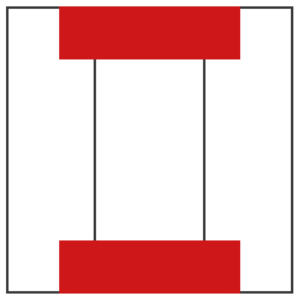

2

3

4