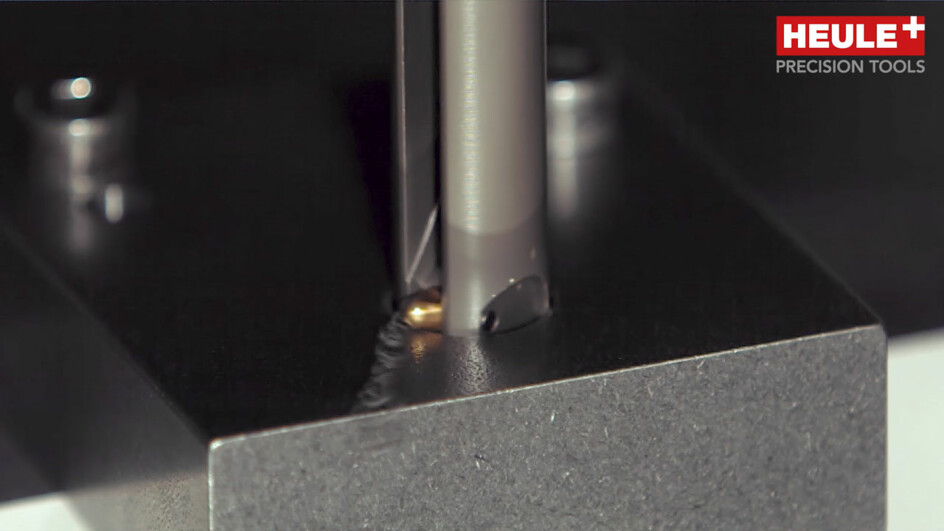

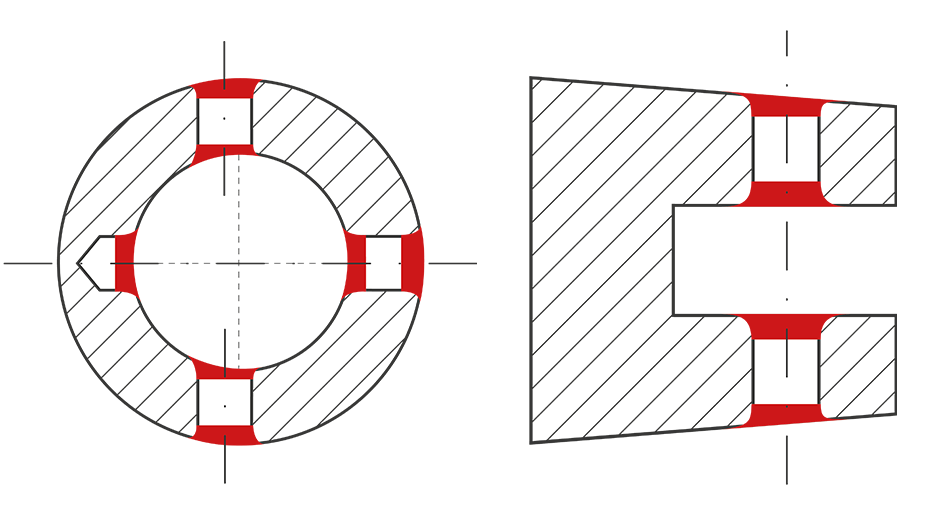

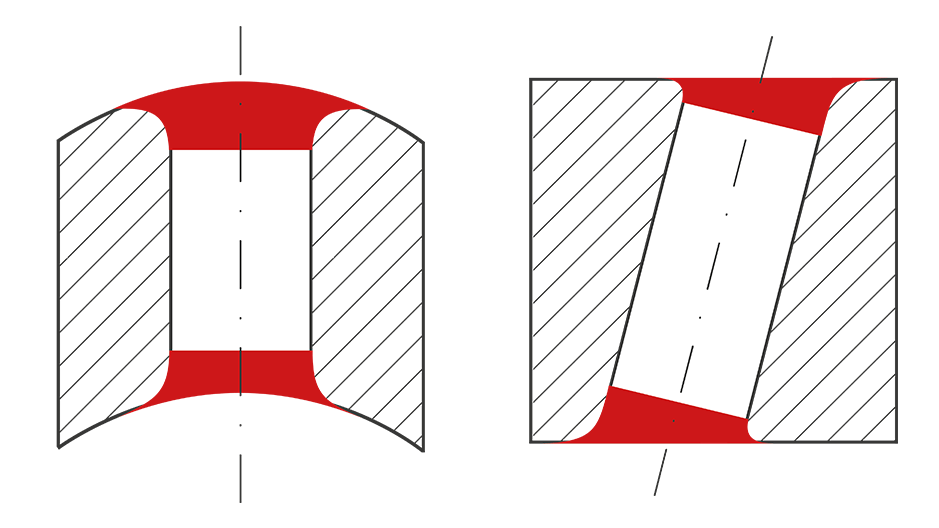

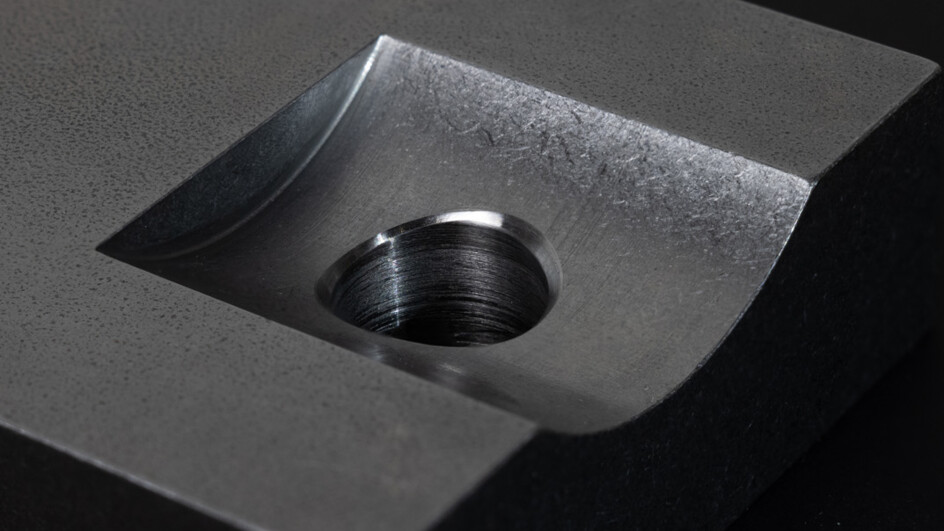

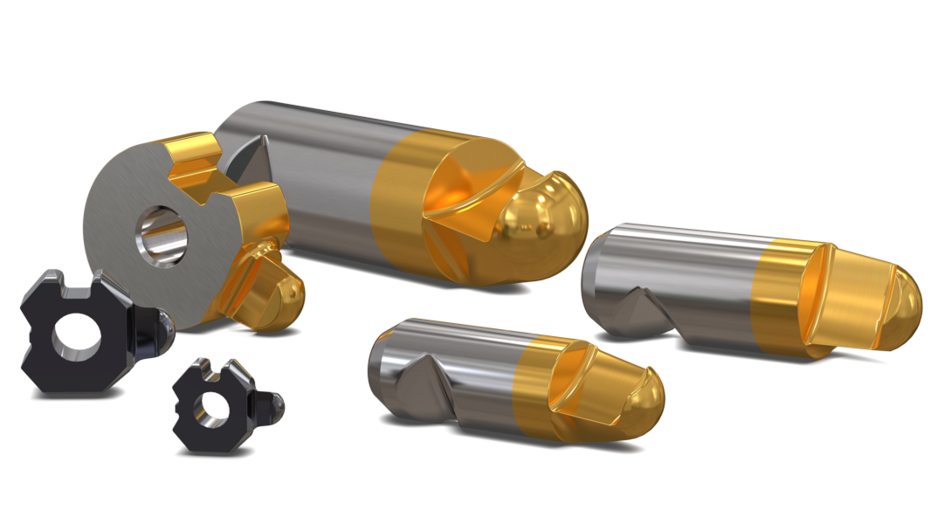

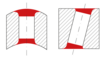

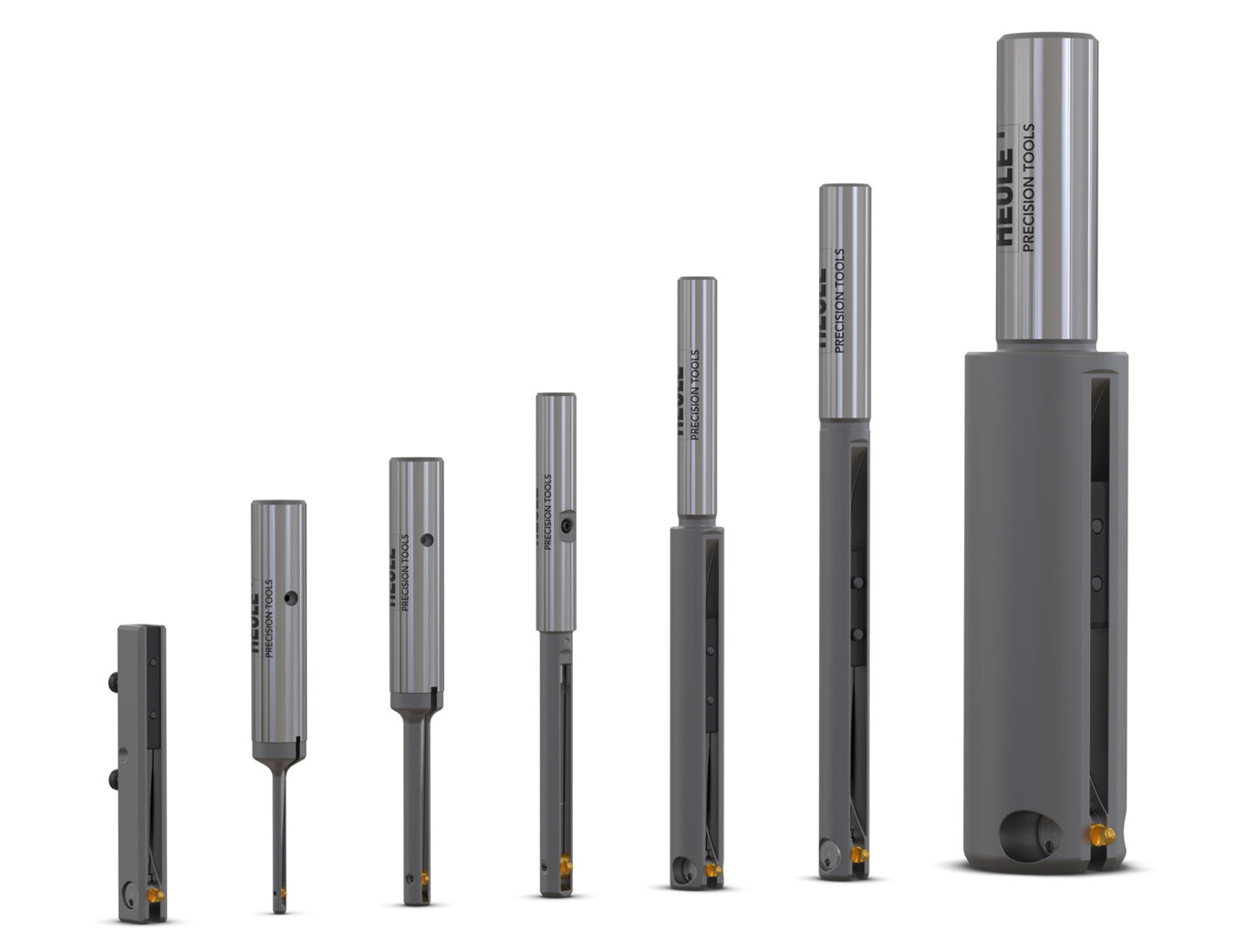

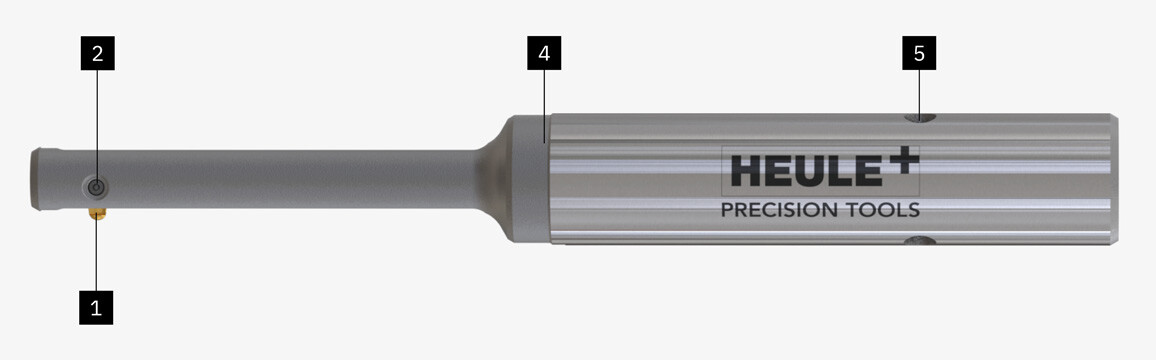

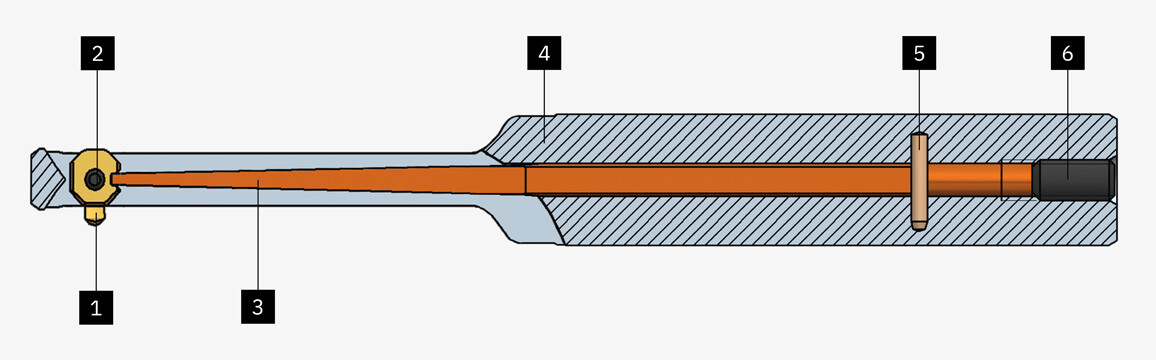

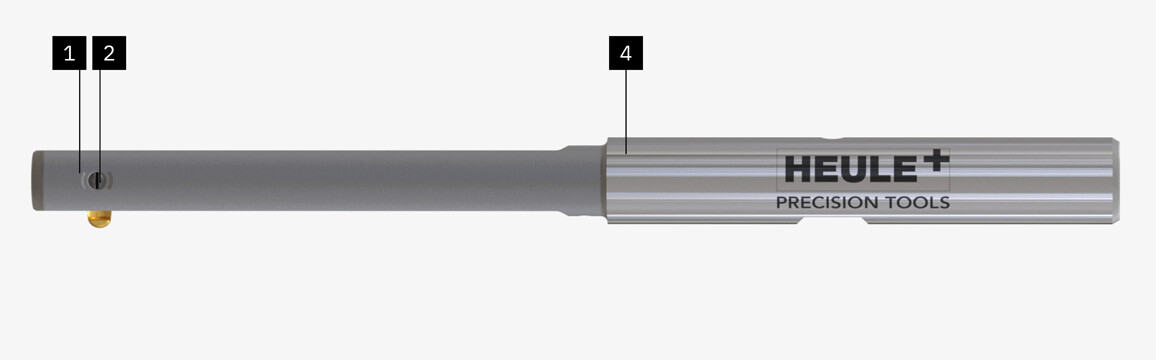

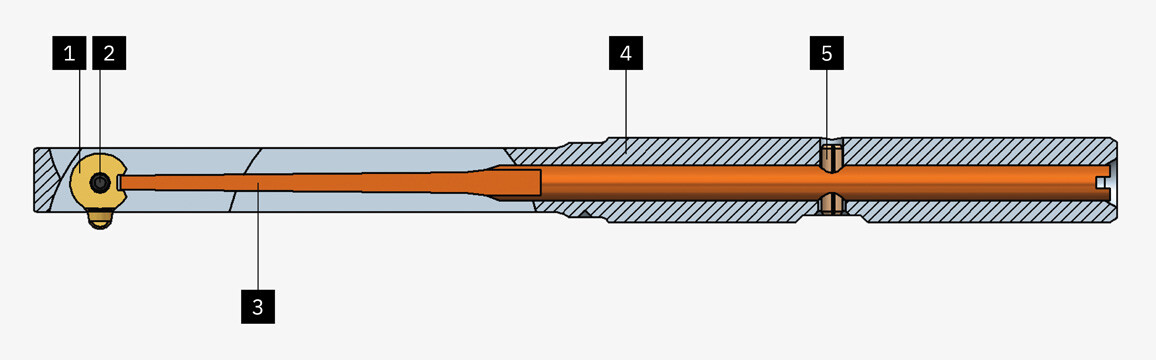

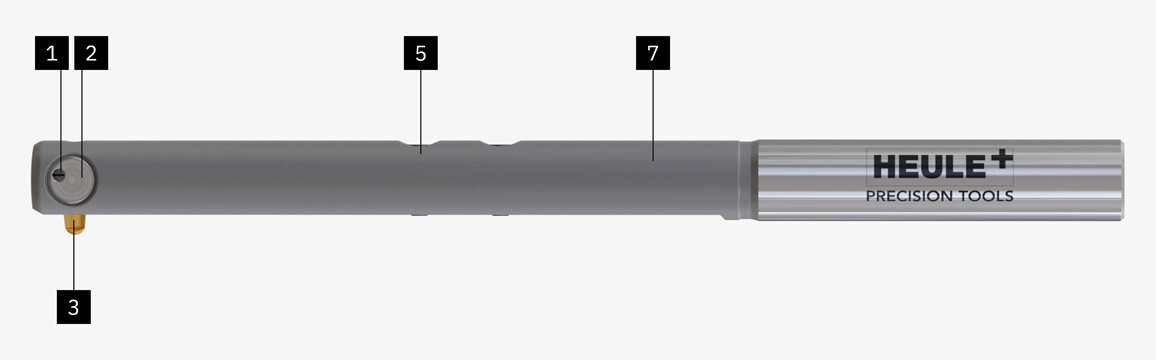

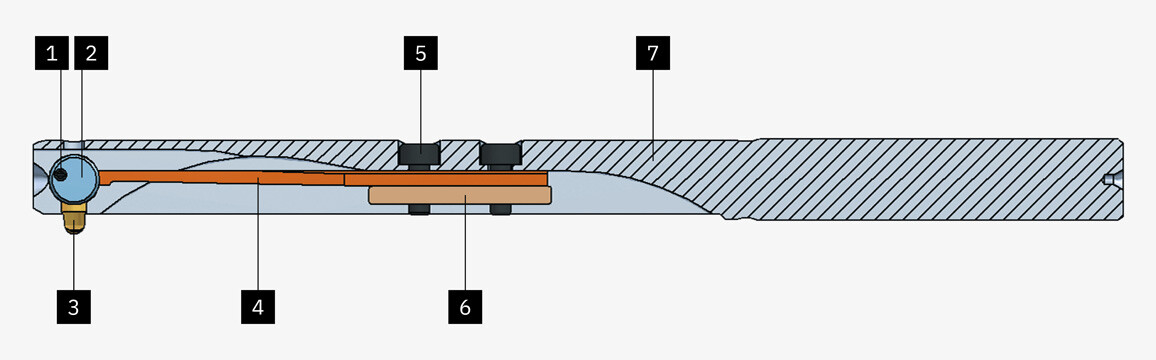

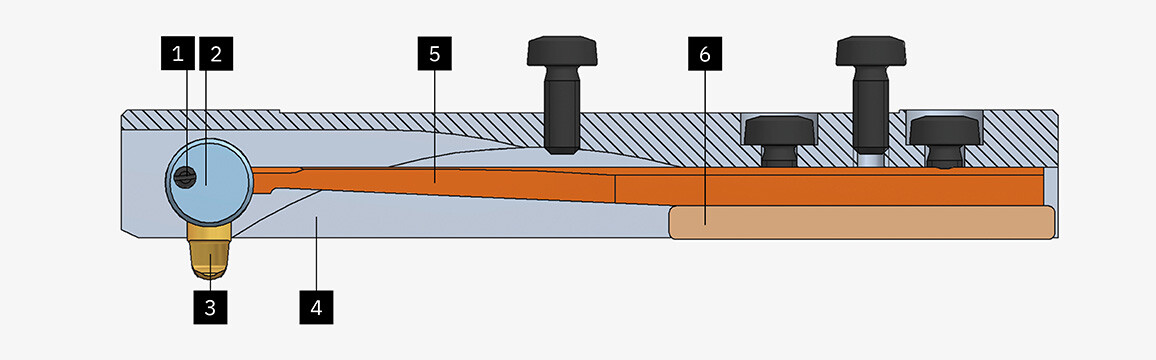

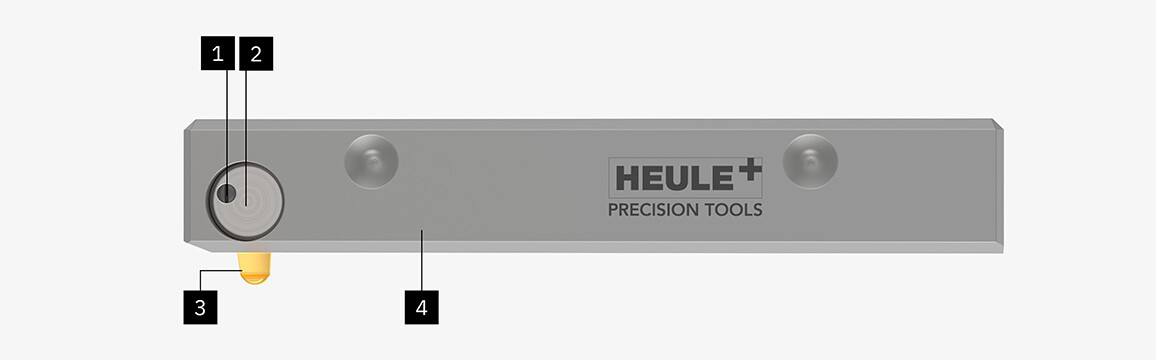

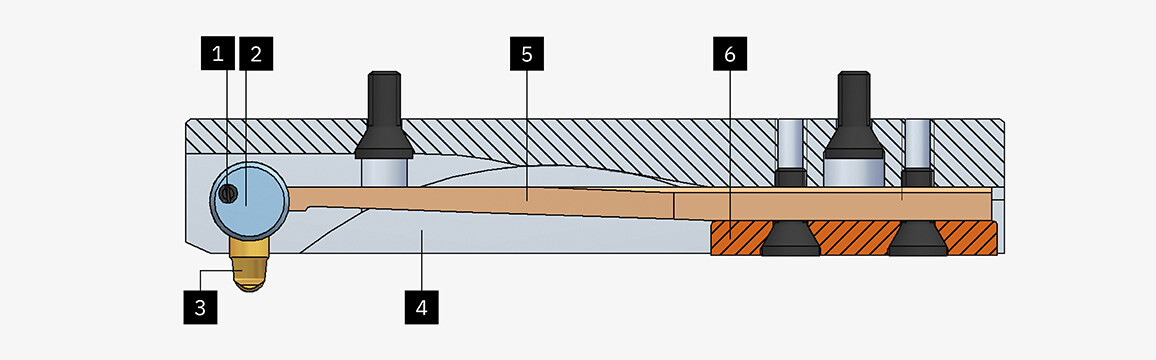

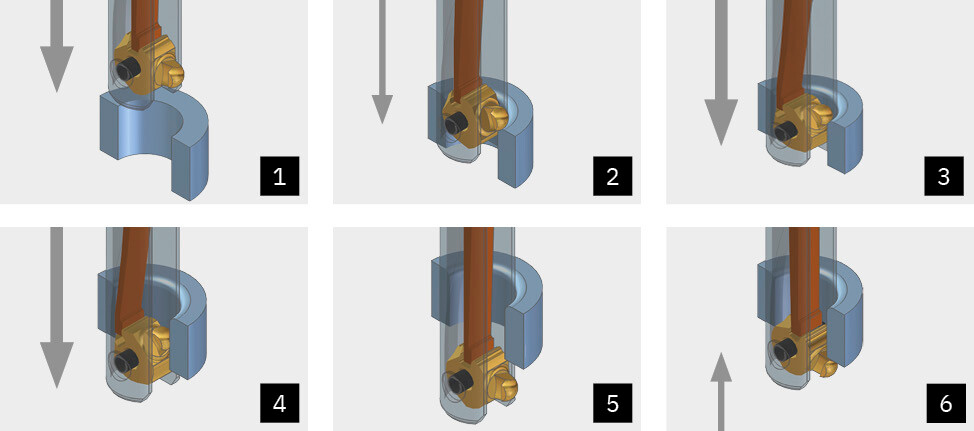

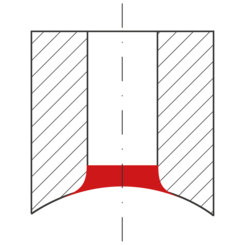

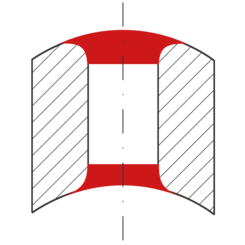

Deburring with COFA is very straightforward. The burr on the front bore edge of the workpiece is removed during forward working feed at working speed. The blade then pivots into the tool body as it enters the bore. The result is a bore edge that has a radius profile and is uniformly deburred.

The tool then moves through the bore in rapid feed without stopping the spindle. The process does not damage the bore’s interior surface. In backwards working feed, the back edge of the bore is then deburred. Once the back deburring is complete, the tool can be removed from the bore in rapid feed.

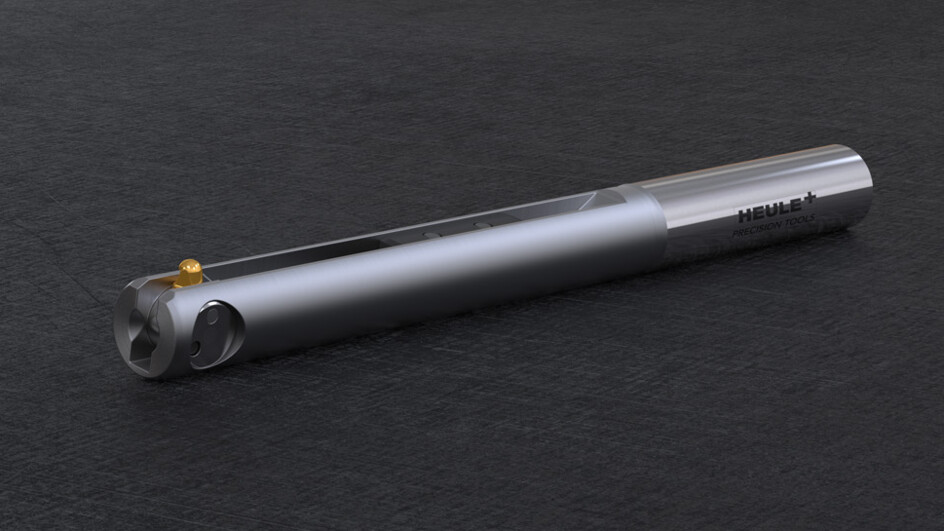

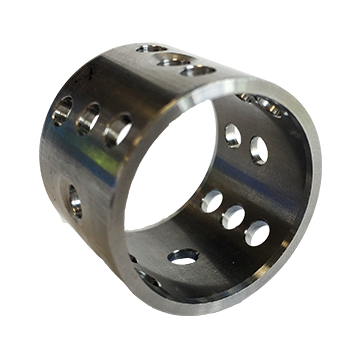

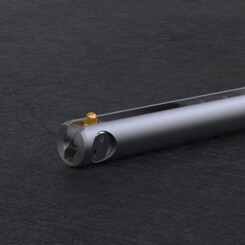

The blade, which can rotate in the tool body, is spring-loaded. As a result, the cutting edge also follows uneven bore edges. This is required, for example, when deburring bores in a pipe. The deburring result is always the same, even if the height of the machining plane changes due to tolerances (e.g. cast parts).